Description

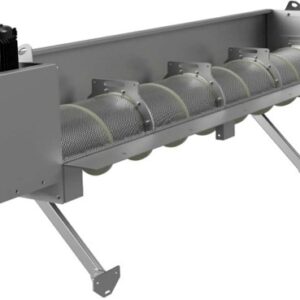

Noggerath® Band Screen Centre-Flo™ the New Generation of fine screening

Noggerath® Band Screen Centre-Flo™ is an innovative wastewater treatment unit for municipal and industrial wastewater treatment. It is definitely the perfect solution for those who want to achieve efficient wastewater treatment and comprehensive environmental protection. In addition to providing long-term reliable performance, the grate offers the following advantages:

1. Innovative chainless drive system.

The Noggerath® Band Screen Centre-Flo™ features a revolutionary chain-free drive mechanism. This drive system consists of a shaft and a pinion, mounted on the outer, clean side of the grille bar and features:

- no accumulation of dirt and grime on the drive elements and a completely free discharge area inside the grill bar.

- the actuator connections are made of oil-impregnated PE, which not only ensures resistance to wear and tear but also a long service life.

- no need to change circuits, ensuring non-stop operation and reducing maintenance costs.

2. Large open filtration area.

The innovative design of the belt grate, where the surface of the belt is parallel to the direction of flow and the effluent reverses direction 90 degrees in both directions and partially downwards after passing through the grate gates and hitting the back wall, offers many advantages:

- the open filtering area increases by up to 90%, which significantly reduces flow losses and at the same time increases the hydraulic capacity.

- The clean side of the screen is strictly separated from the dirty side, which prevents drowned solids from entering the clean side of the water, ensuring cleaning efficiency.

- more efficient collection of sieved materials with lower construction costs, as a smaller channel is sufficient to pass the flow.

3. Increased throughput and maximum retention.

Inspired by nature, Aqseptence group engineers have developed the innovative honeycomb structure sieve Honeycomb Hex Hi-Flow. “The Honeycomb filter plate is very stable and offers many advantages:

- the surface open area is increased by up to 90%, maximising space utilisation and flow capacity.

- less material is needed to produce the mesh, as the hexagonal perimeter is up to 10% smaller than other perimeters of the same area, which reduces the use of resources for production, thus contributing to the preservation of nature.

- minimum drowning materials, maximum retention, guaranteeing high treatment efficiency and protection of downstream treatment plants (e.g. membrane bioreactors).

4. Flexibility and easy adaptability.

The modular design of the belt grate allows the height and width of the belt grate to be optimised to meet the requirements of the channel, the capacity and the pressure loss, thus offering many advantages:

- they can be designed to be easily adapted to existing infrastructures and retrofit projects to improve plant hydraulics and screening efficiency.

- when designing new infrastructures, channel widths can be reduced, saving construction costs.

- the system can be easily equipped with washing and compacting screw presses. Which saves floor space and allows efficient further washing of organic material and recycling of sieved material.

5. Easy maintenance and installation.

The belt grate is a particularly robust and safe unit made of high quality materials. They have a unique, sophisticated design that offers many advantages:

- easy to install, as the base plate assembly is bolted to the floor of the duct and the deflector plates seal the unit to the duct walls.

- no abrasion-sensitive circuitry and the drive mechanism is mounted on the outside of the bar, making them resistant to aggressive sewage environments and reducing maintenance costs.

- the unique honeycomb screen panels are easy to replace in segments, while the dual flushing system and inspection hatches on all sides facilitate maintenance and upgrades.