Description

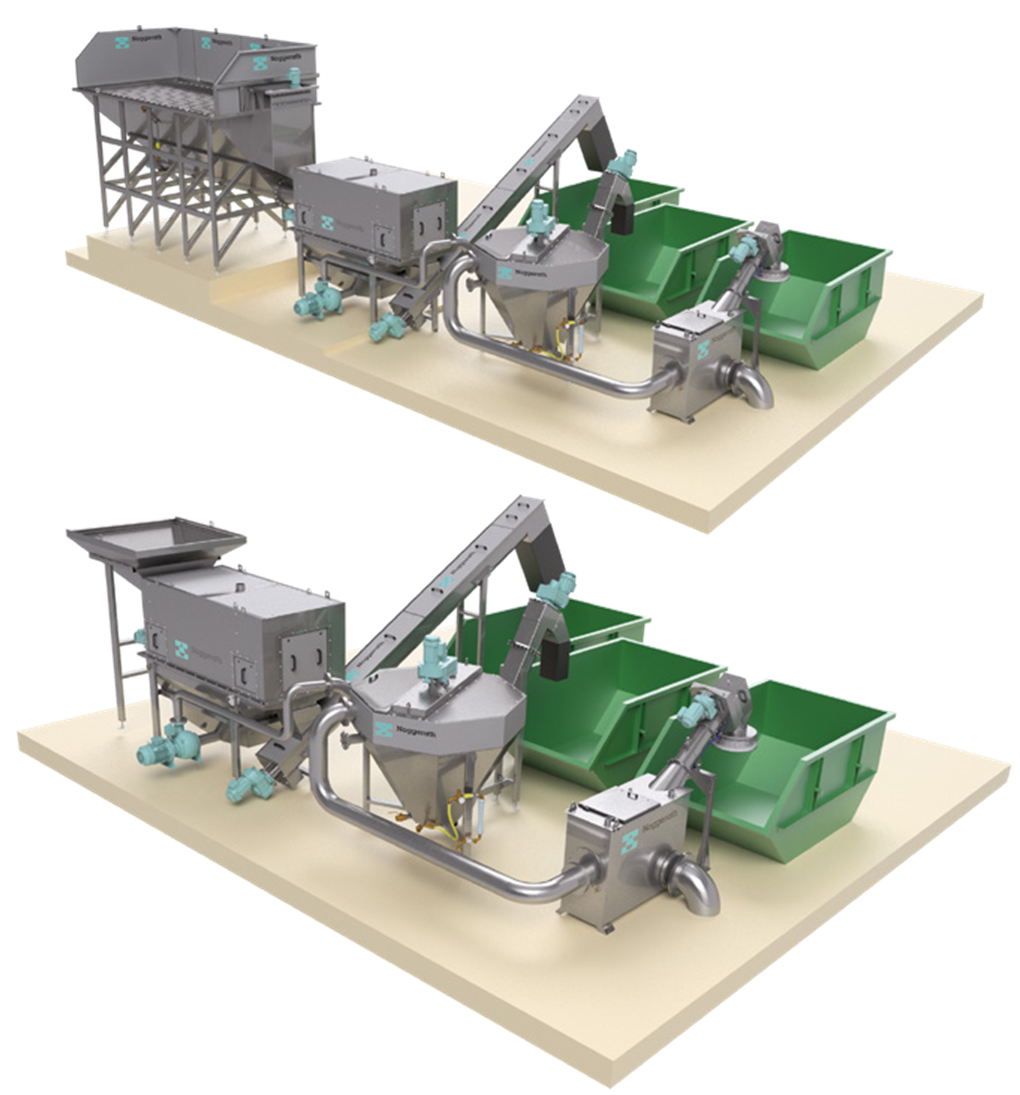

Noggerath® Grit Receiving Stations GRS – an efficient and economical solution for the treatment of sewage grit and cleaning materials

Noggerath® Grit Receiving Stations GRS are designed to receive, dewater, and separate street sewer grit and cleaning materials into different fractions. This process significantly reduces disposal costs and optimizes the operation of the sewage network.

The increasing amount of solids in sewer networks – especially from construction sites, street sweeping or mixed water – poses challenges to the efficiency of the network. Regular removal of such deposits is becoming a necessity, and Passavant-Geiger offers a solution: reliable GRS systems adapted to local conditions.

Functional capabilities

Noggerath® GRS stations offer a wide range of functions for the efficient treatment of various wastewater and sand fractions:

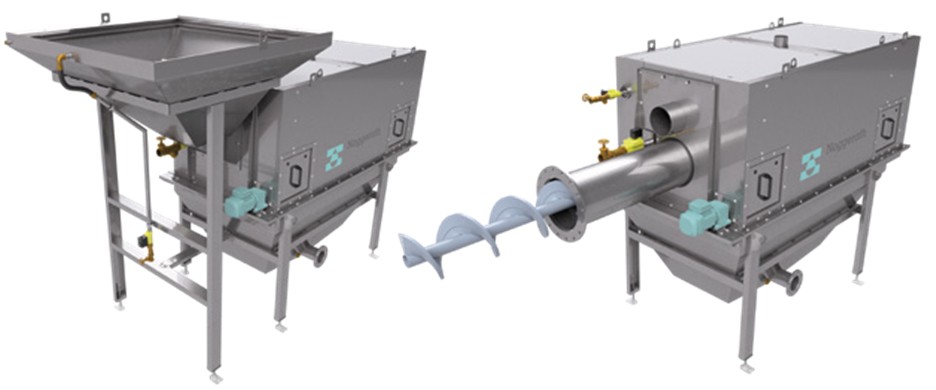

- Receipt and storage – bunkers can be customized as required (concrete or stainless steel)

- Separation and removal of coarse materials – efficient separation of debris and coarse fractions

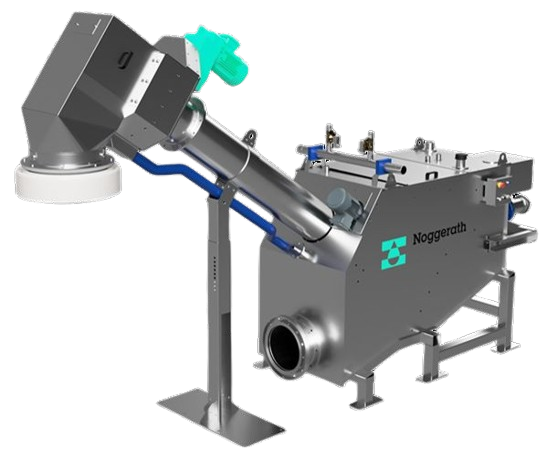

- Sand washing and removal – reduction of organic impurities, increase in dry matter percentage

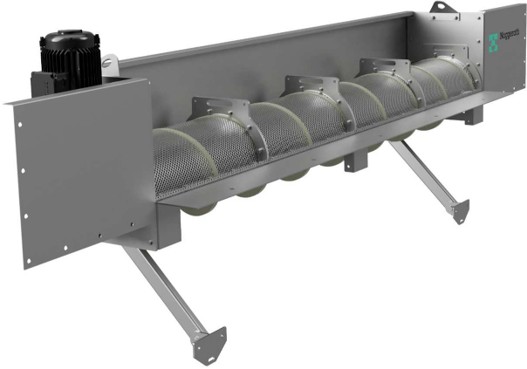

- Optional screening and removal of fine materials – precise and hygienic separation of fractions

- Redirection of treated flows to treatment plants or the sewer network – smart integration of processes into the overall system

Key advantages

- Significantly reduced disposal costs

- Modular design – adaptable to individual needs

- Robust, compact, and reliable equipment

- Ability to treat materials to a hygienically safe level

- An effective solution even when landfill space is limited

Passavant-Geiger solutions are already operating successfully in many regions around the world. A high level of adaptability and reliability, tailored to specific local conditions, guarantees stable and long-term operation.