Description

BioCleaner OS – Biological Wastewater Treatment System

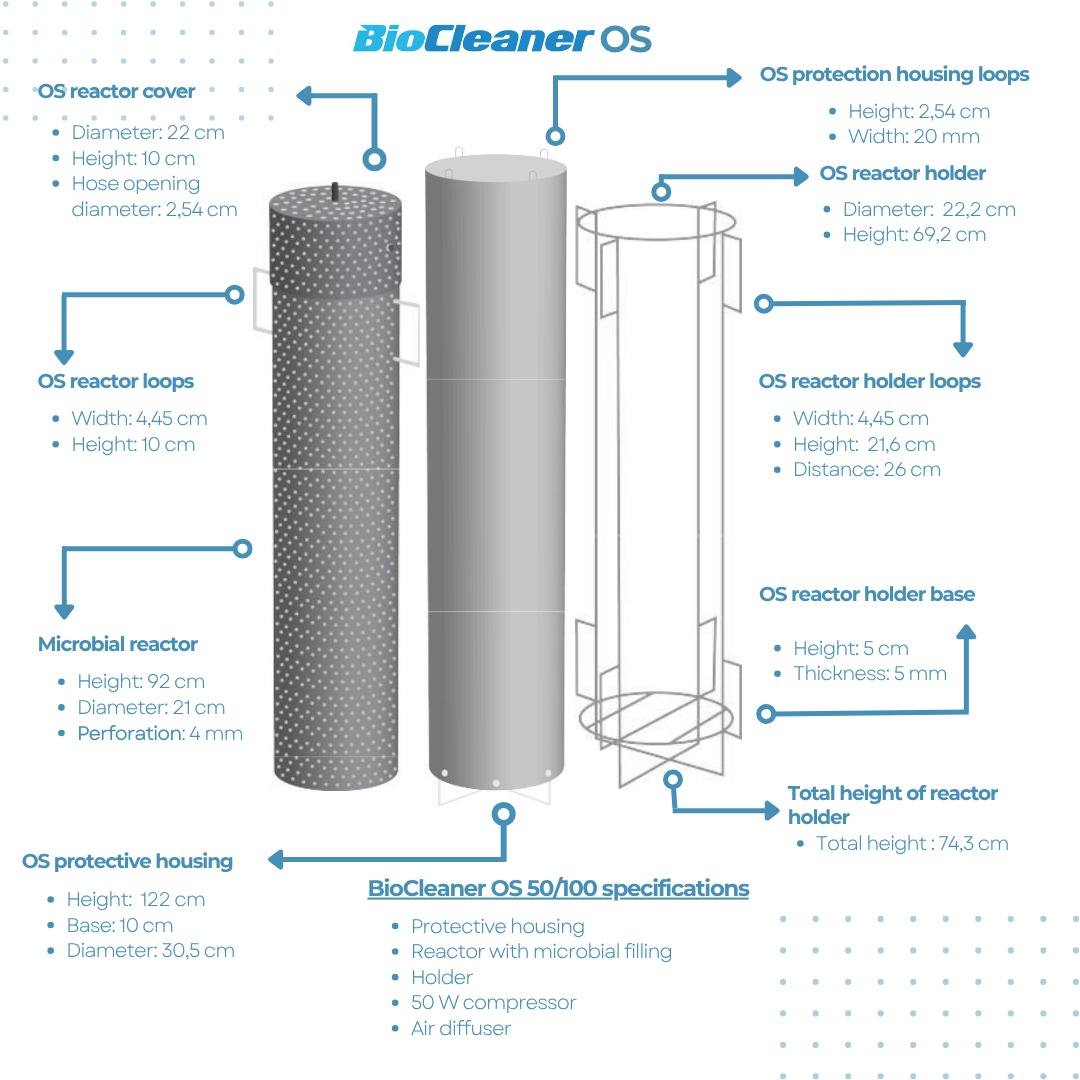

BioCleaner OS is a biological wastewater treatment system based on a patented U.S. technology.

At the heart of the system are microbes that enter wastewater together with oxygen and start multiplying actively. These microbes break down organic pollutants and odor-causing compounds, converting them into simple, harmless elements — carbon dioxide and water.

It is an advanced bioreactor that continuously produces unique, safe microorganisms capable of efficiently degrading organic waste.

BioCleaner OS is a portable unit that consumes very little energy and can be easily integrated into existing infrastructure.

This innovative biological treatment technology eliminates odors, reduces sludge, and improves water quality with minimal effort and cost.

Key Advantages

- Natural microflora – BioCleaner uses facultative, anaerobic, non-pathogenic microorganisms that function effectively under both aerobic and anaerobic conditions.

- Low energy consumption – The combined aerobic–anaerobic process reduces aeration needs by more than 50%, eliminating the need for separate anaerobic reactors and lowering capital costs.

- Sludge reduction – The microbes liquefy bacterial sludge, cutting disposal requirements by up to 90%.

- Natural nitrogen balance – Liquefied sludge increases nitrogen concentration, eliminating the need for external nitrogen supply — particularly beneficial for industrial wastewater.

- High treatment efficiency – The integrated aerobic–anaerobic process removes more than 90% of COD and over 95% of BOD, making it suitable for a wide range of industrial applications.

- Odor elimination – By liquefying sludge, unpleasant odors are completely removed from treatment facilities and treated effluent.

- Nutrient removal – The technology efficiently removes nitrogen and phosphorus, ensuring environmentally safe water discharge.

- Resilience – Immobilized microbes can regenerate and stabilize treatment performance even after adverse operating conditions.