Description

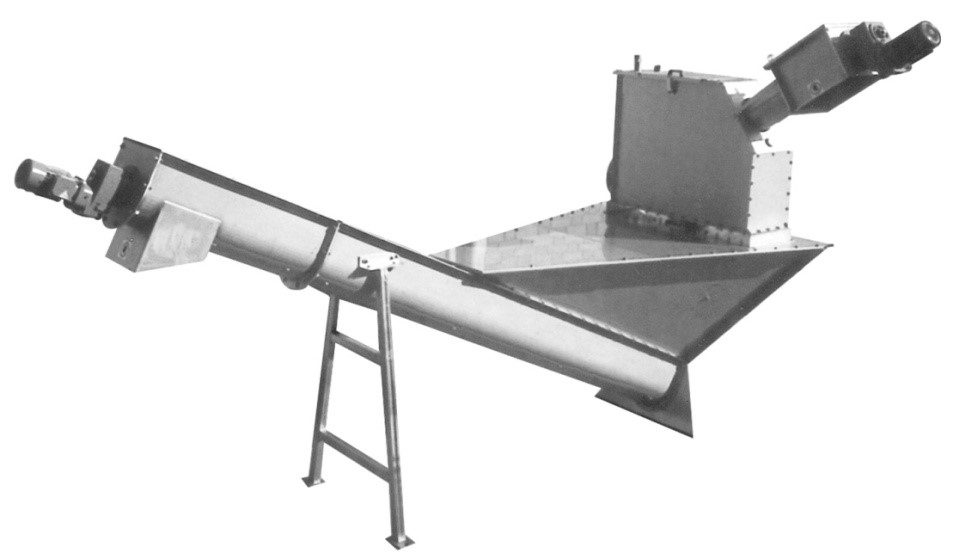

The Noggerath® Combi Eco TOP is an innovative pre-treatment plant configured with a fine mesh and sand separator. In addition, selected sieves or grit scrubbers can be integrated into a fully sealed design for optimum performance.

The Noggerath® Combi ECO TOP is not only an efficient but also an innovative solution that ensures a high standard of cleaning.

Benefits:

- No space required. All mechanical treatment processes are carried out in one system, so there is no need for a large amount of space for installation and operation. This is particularly useful in areas where space is limited, as it allows efficient use of the available area and reduces construction time and costs

- Low construction requirements. The unit performs the work of three units in one, eliminating the need to install and connect three separate units. It is designed and constructed for easy and quick installation. This saves time and labour resources.

- Extensive customisation possibilities. The Combi ECO TOP can be configured to your requirements and specifications, adapting to old treatment plants and new builds and treating wastewater in the most efficient way.

- Robust and reliable construction. The unit is constructed from the highest quality stainless steel with additional machining and easily replaceable parts for easy maintenance and durability.

- No bearings in contact with waste water. The unit is designed so that there are no bearings in contact with waste water that could be damaged or worn out more quickly by contact with waste water. This prolongs bearing life and reduces maintenance costs.

- High quality, reliability at an affordable price. This unit combines quality, efficiency and reliability with an attractive price, enabling users to achieve an efficient wastewater treatment result without a large investment.

- Durability and reliability. Spare parts availability over many years and short delivery times thanks to in-house production and modern storage.

These advantages make Combi ECO TOP pre-treatment systems an attractive alternative to other wastewater treatment plants. Without sacrificing the ability to maintain high standards of quality, reliability and hygiene, and with an economic advantage.

For information on the installation on the Academy campus, see there