Description

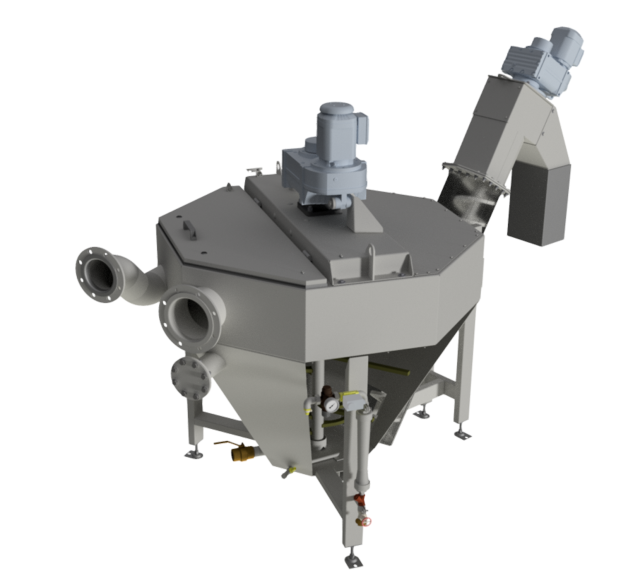

Noggerath® Grit Washer GWC -Successful concept for municipalities and industry:

Noggerath® Grit Washer GWC”s upstream method and patented fixed bed process means that the sand leached from the effluent contains less than 3% organic matter. The mass of waste after washing can be reduced by up to 85% depending on the type of raw material. This not only allows the leached sand to be reused, but also saves on waste transport and storage costs. The organic matter returned increases the availability of nutrients in downstream wastewater treatment processes, which reduces the need to add additional organic matter for the denitrification process.

These advantages of theNoggerath® Grit Washer GWC provide a comprehensive picture of its functionality and benefits when it comes to effective sand treatment, cost reduction and environmental protection:

Benefits:

- Minimum organic matter content of leached sand. No more than 3% of organic matter remains in the leached sand from the effluent, ensuring an optimal treatment process.

- Re-use of grit. The reuse of leached sand significantly reduces the amount of sand discharged and ensures long-term environmental protection.

- Efficient savings in transport costs. Significantly reducing the weight of waste, depending on the type of raw material, saves transport and storage costs.

- Increase in organic nutrient reserves. The reuse of leached organic matter reduces the need to add nutrients for the denitrification process, thereby improving gas production in anaerobic sludge treatment.

- Reliable and durable construction. The screw and agitator are mounted only on the actuator, which facilitates installation and maintenance as there is no installation medium.

- Efficiency and productivity. The Noggerath® GWC sand washer operates in continuous mode, resulting in high hourly throughput and very low water consumption.

- Optimum cleaning effect. The slow movement of the sand grains and the low turbulence in the washing zone ensure optimum cleaning effect.

- Patented fixed layer process. The unit uses Noggerath®’s patented fixed layer process, which provides protection against the release of unwashed sand.