Description

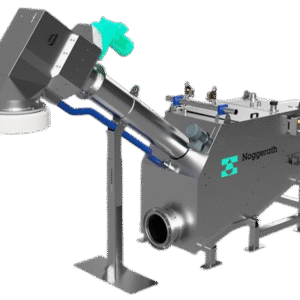

Noggerath® Septage Receiving Station NSI-SRS – innovative and reliable solution for automatic treatment of incoming sewage

The Noggerath®Septage Receiving Station NSI-SRS is a combined plant consisting of a screen, a spiral conveyor, a screenings compactor and an additional washing area. It is designed for the automatic mechanical treatment of effluent discharged from vacuum trucks and collected from tanks.

This Noggerath® Septage Receiving Station NSI-SRS station is made of stainless steel, has a hermetic tank and an Spiral Sieve NSI. The spiral screen included in the package is the best-selling grating of its type in the world. Due to its quality and versatility and its high operational reliability. This unit stands out for its ability to handle incoming wastewater efficiently, saving time, resources and the environment:

Advantages:

- Efficiency. The Perrot connector with automatic clamping valve and the connection for measuring the discharge parameters control the efficient discharge of wastewater and the odor shut-off.

- Versatility and Compactness. The unit covers all the most important pre-treatment processes, yet is compact and easily adaptable to different site conditions.

- Technological Innovation. With the revolutionary Noggerath® Radial Eco Drive RED technology, the removal of screened materials will be ensured without any clogging. The use of this drive reduces the need for maintenance and increases additional safety for workers by eliminating the need for manual unloading of sifted waste in the unloading area.

- Hygiene and environmental protection. Integrated automatic compaction zone and tank flushing systems ensure smooth and hygienic reception, treatment and environmental protection.

- Durability. High-quality stainless steel and engineered solution components ensure long-lasting and reliable use, even under extreme conditions.

- Easy Integration. The modular assembly allows the unit to be easily adapted and integrated into existing wastewater treatment systems.

The Noggerath® Septage Receiving Station NSI-SRS is not only a technological device, but also an efficient solution for the treatment of incoming wastewater, helping to keep the environment clean and safe.

How it works

Effluent from tanks or sewage trucks is fed through a Perrot connection with an automatic valve into the reservoir and the inner surface of the grate basket, which is open on the inlet side. At this stage, the solid particles cover the surface of the basket, creating obstacles to the free flow of the liquid, so the liquid level in front of the screw grates gradually increases. An upstream level measuring device monitors the liquid level. When this level reaches or exceeds the set maximum level, the conveyor drive automatically turns on. A spiral brush attached to the screw, which is installed against the direction of transport, effectively cleans the screen surface. This brush prevents clogging of the openings and lifts the solids onto the screw conveyor. The retained solids are transported by a rotating auger to the disposal area and on the way they are drained, compacted and removed into a container.

Sifted wastewater is sent through the outlet for further treatment. When the liquid level drops below the set level, the screw conveyor automatically shuts off and the unit is ready for a new cycle.

Specification

| NSI – SRS |

300 |

500 |

700 |

| Posvyris [°] |

35 |

| Sieto krepšys / strypinis sietas Ø [mm] |

267 |

451 |

705 |

| Konvejerio spiralė Ø [mm] |

195 |

295 |

| Sieto anga [mm] |

Perforacija Ø 2–10

Plyšys 0,25– 6

|

| Debitas* [m³/h] * Priklausomai nuo kietųjų dalelių kiekio, fekalinis dumblas, kuriame yra ne daugiau kaip 2–3 % sausųjų medžiagų |

maks. 30 |

maks. 50 |

maks. 100 |

| Sausųjų medžiagų kiekis išleidžiamose medžiagose (%) |

iki 35 |

| Išleidžiamų atliekų kiekio sumažėjimas (%) |

iki 60 |

| Pavaros blokas [kW]

(400V/ 50 Hz)

NSI-SRS |

0,55 |

1,1 |

| -RED [kW] |

0,75 |

1,5 |

|

|

|

|

|

|

| Komponentai |

Medžiaga |

| Talpykla, rėmas, atrama |

Nerūdijantis plienas AISI 304 (1.4301) arba AISI 316L (1.4404), kiti pagal pageidavimą |

| Sieto krepšys arba strypinis sietas |

Nerūdijantis plienas AISI 304 (1.4301) arba AISI 316L (1.4404), kiti pagal pageidavimą |

| Spiralė |

Specialus mikro legiruotasis plienas arba nerūdijantis plienas AISI 304 arba AISI 316 |

| Krumpliaračio, pavaros segmentai |

Nailonas (poliamidas) |

| Jungiamosios detalės |

Žalvaris arba ner9dyjantis plienas |

| Sandarinimo juostelės |

Guma |

| Valymo šepetys |

Korpusas iš polietileno (PE)

Šepetys iš nailono (poliamidas) |

Šiame pristatyme pateikti techniniai duomenys yra tik orientaciniai ir turi būti nustatomi kiekvienu konkrečiu atveju. Galimi techniniai pakeitimai.

Additional options

Options (all relevant components are also included in the Ex protection system)

- Maintenance openings.

- Removal box.

- Extension of removal

- Bagging system.

- Removal chute.

- Emergency stop button.

- Level measurement.

- Protective heating against freezing.

Control system: PLC Siemens (with or without SCADA connection) A supervisory control and data acquisition (SCADA) system is a control system consisting of computers, network data communication and graphical user interfaces (GUIs) for high-level processes.