Description

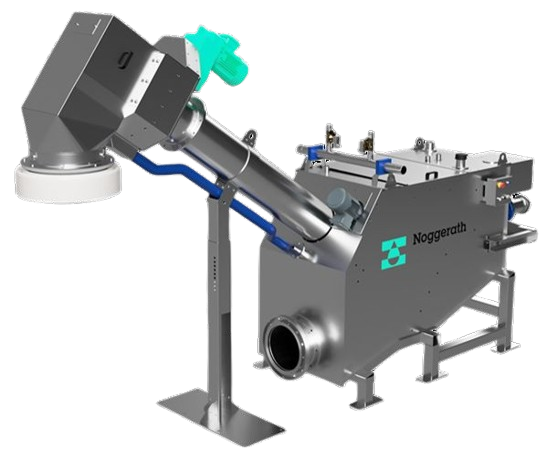

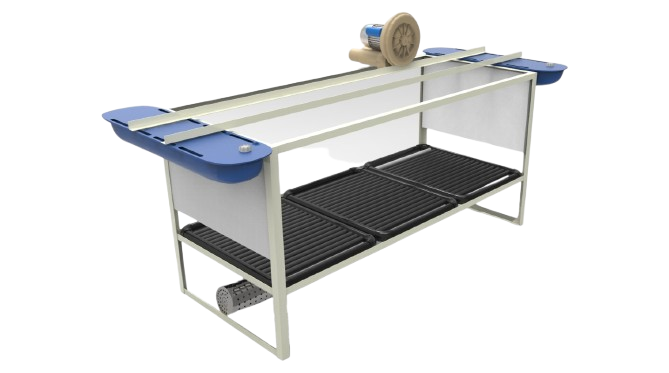

Noggerath® Septage Receiving Station RBS-SRS-RED – reception and treatment of transported wastewater

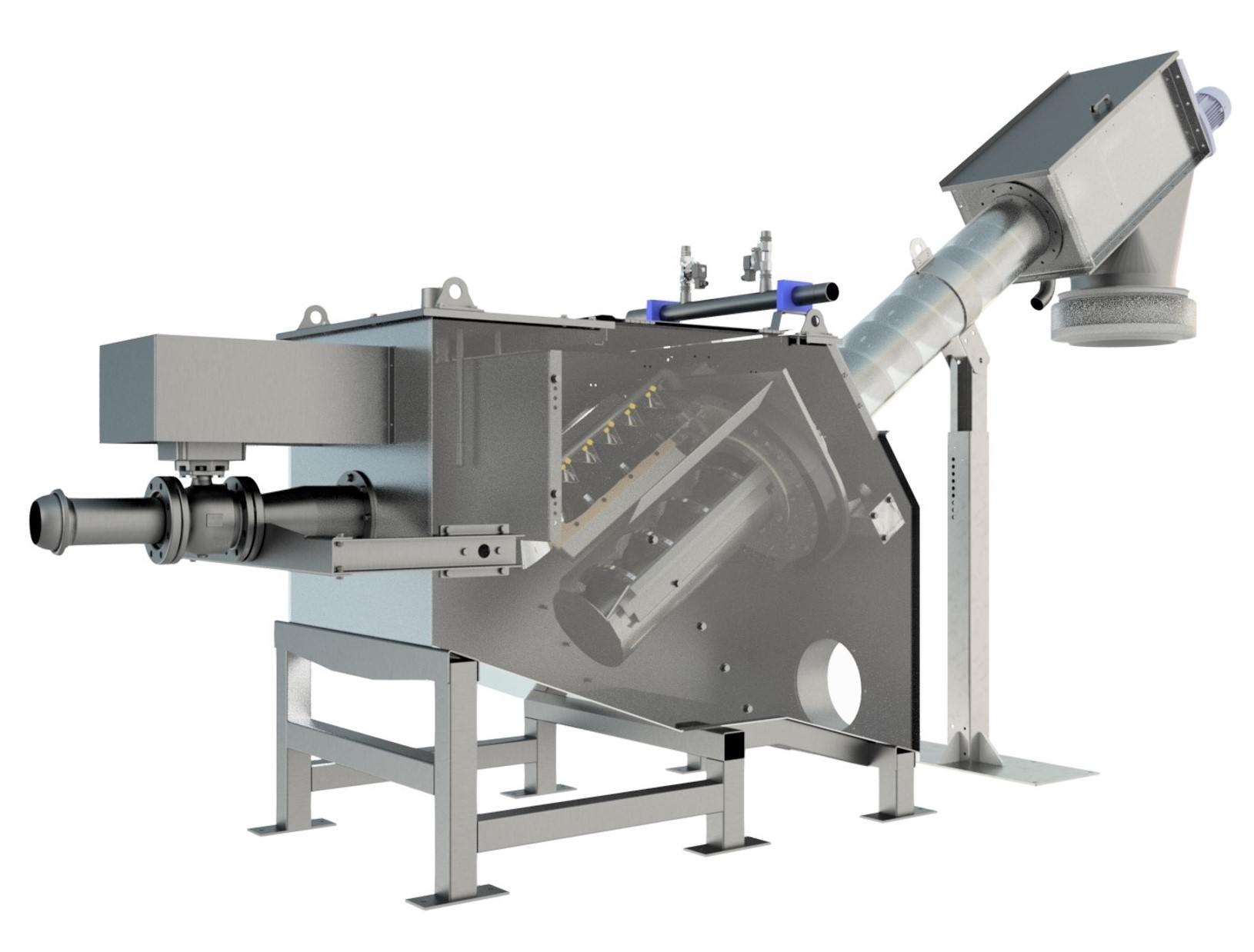

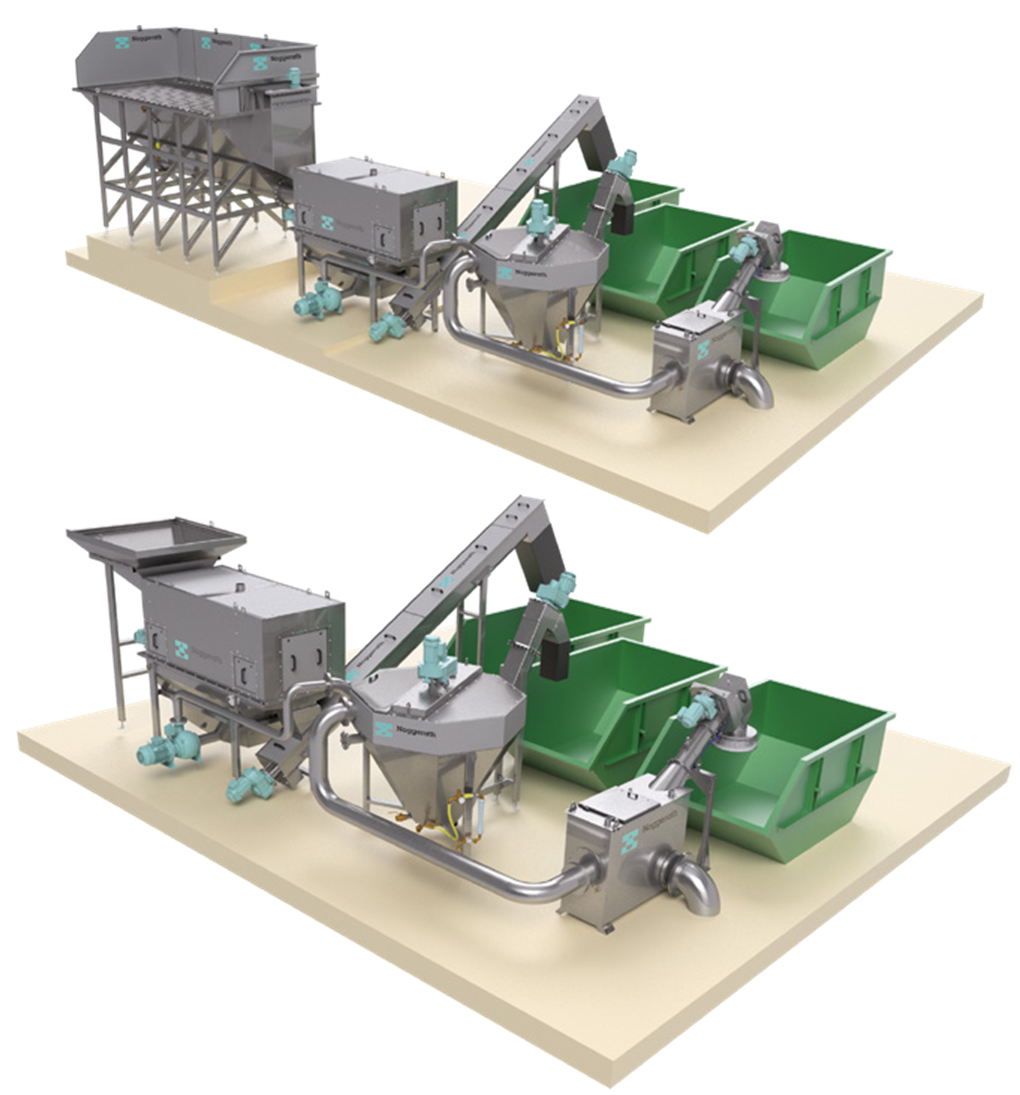

Noggerath® Septage Receiving Station RBS-SRS-RED is a combined automatic mechanical wastewater treatment plant designed for wastewater discharged from vacuum trucks. The plant combines a drum screen, a spiral conveyor, a compactor for screened waste and an additional washing zone.

The Noggerath® RBS-SRS-RED is made of stainless steel and has a sealed tank and a bar screen with a flow-optimizing PAPRO profile (ß = 0.84). This device stands out for its ability to efficiently manage incoming wastewater, saving time, resources, and the environment:

Advantages:

Independent operation of the cleaning element and spiral conveyor. Ensures maximum flexibility and reliability even with high wastewater flows.

No suspended swing arm in the inlet area. Reduces the risk of clogging and improves hydraulic efficiency.

No drive elements in the outlet area (RED – Radial Eco Drive). Aaxial discharge without clogging using the Noggerath® Radial Eco Drive RED drive.

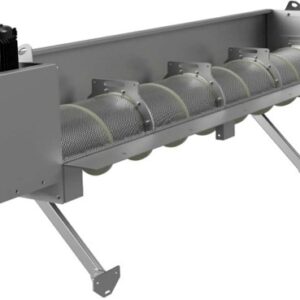

Sustainable separation and compaction of solids. Sieved particles are collected, washed and compacted in one place and can be safely transferred to a container immediately.

Automatic screen washing – reduced maintenance requirements, clean and smooth operation.

Bar screen with flow-optimized PAPRO profile (ß = 0.84) – lower pressure losses, maximum flow and high cleaning efficiency due to better penetration of the cleaning teeth.

High resistance to solid matter concentration – ideal for screening septic sludge, train toilets, industrial wastewater reception and screening.

RBS-SRS – RED Septage Receiving Station is a highly effective solution for receiving and treating wastewater, helping to keep the environment clean and safe.