Description

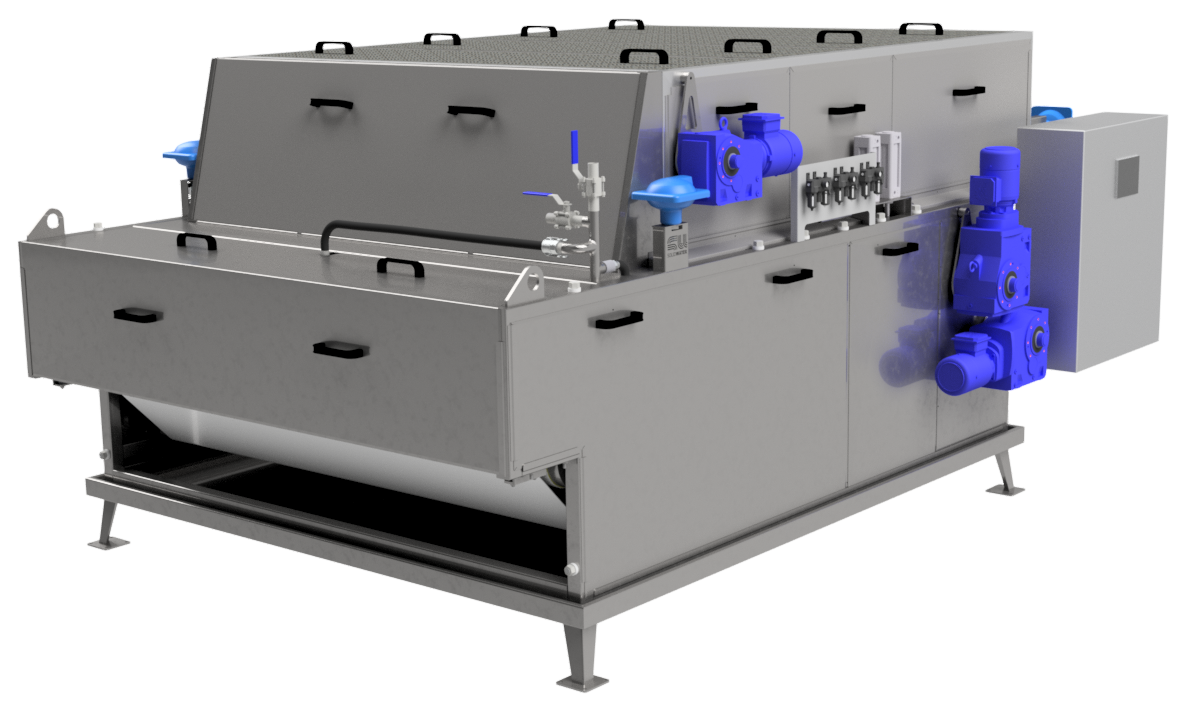

SW Belt Sludge Thickener BT – efficient and economical sludge thickening

The SW Belt Sludge Thickener BT is a reliable solution for thickening municipal and industrial wastewater sludge. Its stainless steel construction ensures durability, while its compact design allows for optimal use of space. With its high performance and low operating costs, this device helps to efficiently remove liquid from sludge, reduce wastewater treatment costs, and facilitate maintenance.

Advantages:

- High performance and low costs. Thanks to pneumatic or hydraulic belt centering, a large working surface, and specially designed plows, sludge dewatering is efficient, using less polyelectrolyte and electricity

- Optimization and cost savings. The ability to integrate into cascade systems with SW FTB belt sludge presses allows for optimal use of space and reduces the need for additional thickeners.

- Durability and resistance. The stainless steel body and many years of manufacturing experience ensure wear resistance and a long service life.

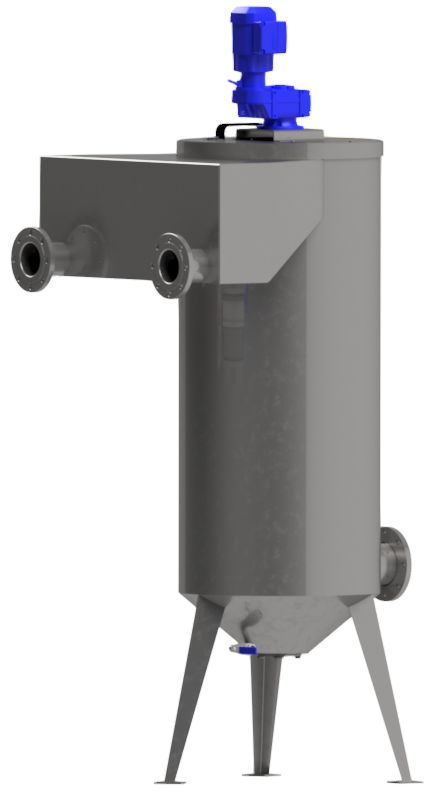

- Automatic polymer dosing system. Ensures optimal use of polyelectrolyte, effectively controls the flocculation process, and reduces operating costs.

- Easy maintenance and servicing. The robust design and easily accessible parts allow for quick technical servicing.

- Quiet operation. Low noise levels improve the comfort of the working environment and increase employee productivity.

- Economy ntages:and sustainability. Filtrate and wash water can be reused, reducing costs and ensuring sustainable use of resources.

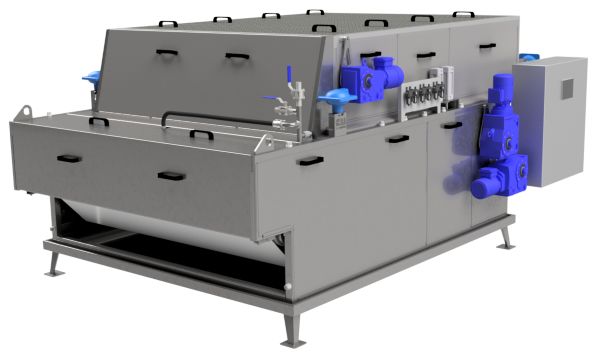

How it works

SW Belt Sludge Thickener BT Operation

The main purpose of this device is to reduce the volume of sludge before further treatment stages. SW Belt Sludge Thickeners BT operate on the principle of gravity: sludge is filtered through a special fabric that effectively separates liquids from solid particles.

The process takes place in several stages:

- Sludge feeding and distribution. The flocculated sludge is fed through a feed chute located above the tension shaft and evenly distributed on the filter belt. The distribution plate ensures uniform distribution of sludge across the entire working width of the belt.

- Gravity thickening. Special adjustable plows form channels in the sludge mass, which improve water drainage and accelerate the thickening process.

- Sludge transport. A slow-moving filter belt transports the sludge to the discharge area. The thickened sludge is separated from the belt and directed to the transport device.

- Filtrate management and reuse. The water separated during flocculation drains away automatically and can be used for washing, thus reducing costs.

- Belt cleaning. The special fabric filter belt is cleaned by flat jet nozzles located in the washing chamber. The washing system has a self-cleaning device that ensures efficient nozzle operation and clean collection of washing water.

Finally, the thickened sludge is ready for further processing using dewatering equipment.

Specification

Municipal and industrial sludge thickening

*Depending on sludge type

| FTP |

Belt width (mm) |

Unit width (mm |

Load (kgDS/h) |

*Capacity (m³/h) |

| 500 |

400 |

1100 |

100-200 |

maks. 7 |

| 900 |

800 |

1500 |

150-300 |

maks. 12 |

| 1200 |

1100 |

1800 |

200-400 |

maks. 20 |

| 1500 |

1400 |

2100 |

300-580 |

maks. 28 |

| 1900 |

1800 |

2500 |

400-750 |

maks. 38 |

| 2300 |

2200 |

2900 |

500-900 |

maks. 48 |

| 2800 |

2700 |

3400 |

600-1200 |

maks. 60 |

The technical data provided in this presentation is for reference only and must be determined on a case-by-case basis. Technical changes are possible.