Description

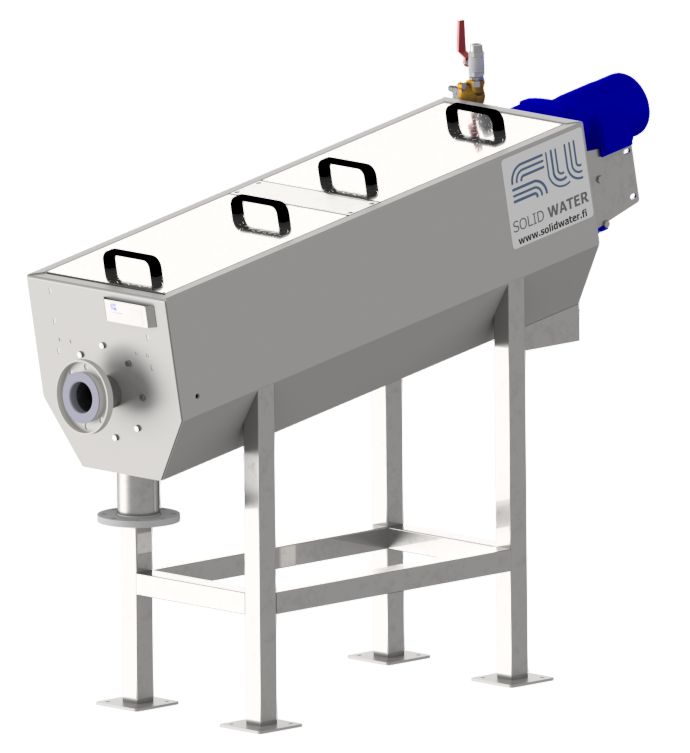

SW Drum Sludge Thickener – An Effective and Reliable Solution for Your Processes

The SW Drum Sludge Thickener is an innovative, high-quality device designed for effective sludge thickening and volume reduction. Its advanced technology allows for exceptional performance with minimal energy consumption, ensuring reliable and economical operation. Made of high-quality stainless steel (AISI 304 or AISI 316), this thickener is durable, easy to maintain, and adaptable to various industries. Its closed design prevents unpleasant odors from escaping, keeping the working environment clean and comfortable.

Advantages:

- High performance and energy savings – ensures efficient sludge thickening with minimal energy consumption.

- Reliable process – simple, time-tested technology that operates stably and does not require significant labor costs.

- Wear resistance – made of high-quality stainless steel or acid-resistant steel, durable and corrosion-resistant.

- Automatic polymer dosing system – this optional extra optimises the flocculation and sludge dewatering process, reducing operating costs.

- Easy maintenance and servicing – robust construction with easily accessible parts allows for quick servicing.

- Low noise level – ensures a comfortable working environment and reduces noise pollution.

- Flexible adaptation – a choice of different sizes and additional functions to suit individual needs.

- Odor control – closed design prevents unpleasant odors from escaping into the environment.

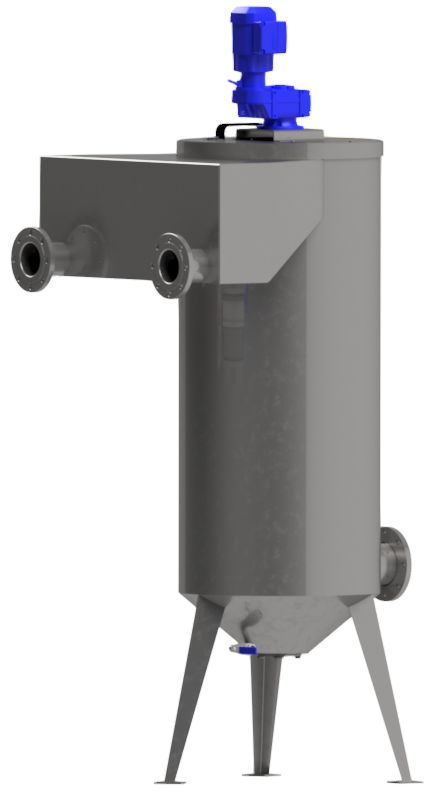

The SW Drum Sludge Thickener can be purchased as a separate unit or integrated into the SW Belt Sludge Filter Press FTP.

It’s a solution you can count on. Optimize your wastewater treatment processes with a reliable and cost-effective device that ensures smooth operation and minimal maintenance!

How it works

The main purpose of a sludge thickener is to reduce the volume of sludge before further sludge treatment stages. These SW drum thickeners operate on the principle of gravity, filtering the thickened sludge through a special fabric. The filter fabric is tightly stretched around a steel cylindrical frame.

During operation, the sludge mass is fed into the center of the thickener, where it is spread by the deflector blades and pushed to the other end of the thickener. There, it is retained on the filter fabric, while the filtered water is discharged to the next stage of wastewater treatment.

Rotating in a circle, the sludge scraper pushes the sludge into a receiving pit in the center of the thickener, from where the sludge is fed to the next stage of treatment. The sludge thickener is of a closed design to prevent the spread of odors. The gases produced are collected and cleaned to ensure environmental protection.

To improve thickening efficiency, polymers can be added to the thickening process to form sludge flocs, which are then easier to separate.

In some cases, drum thickeners can be equipped with an automatic control system that regulates the speed and efficiency of the thickening process according to the sludge flow conditions and density level.

Specification

*Depends on sludge type

| DT |

Drum diameter(mm) |

Drum length (mm) |

*Capacity (m³/h) |

| 400/1300 |

400 |

1300 |

maks.4 |

| 500/1300 |

500 |

1300 |

maks.6 |

| 500/2500 |

500 |

2500 |

maks.13 |

| 600/1800 |

600 |

1800 |

maks.10 |

| 600/2300 |

600 |

2300 |

maks.16 |

| 600/2800 |

600 |

2800 |

maks.22 |

| 800/2800 |

800 |

2800 |

maks.30 |

Example 1% DS feed 4-8% DS output, depending on sludge types and volume.

The technical data provided in this presentation is for reference only and must be determined on a case-by-case basis. Technical changes are possible.

Application and areas of activity

The SW drum thickener for sludge dewatering can be used for:

- Municipal and industrial wastewater.

- Textile printing and dyeing.

- Galvanic industry.

- Paper production.

- Leather processing.

- Beer industry.

- Food processing industry.

- Oil refining.

- Chemical industry.

- Pharmaceutical industry.

- Sludge dewatering in ceramics and other industries.