Description

SW Flocculator – for an optimal flocculation process

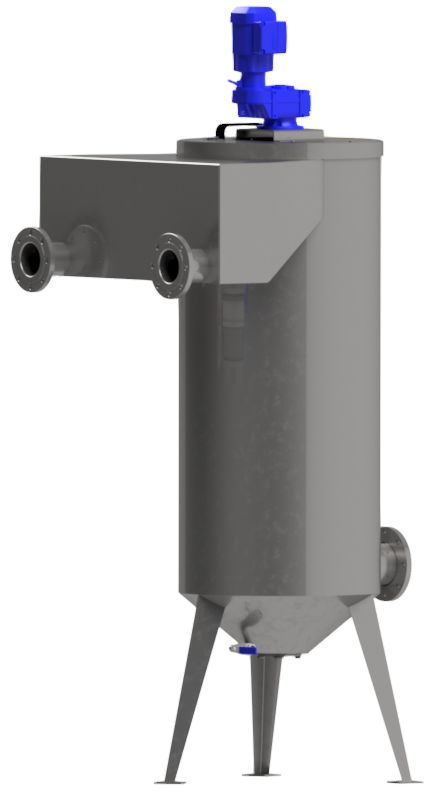

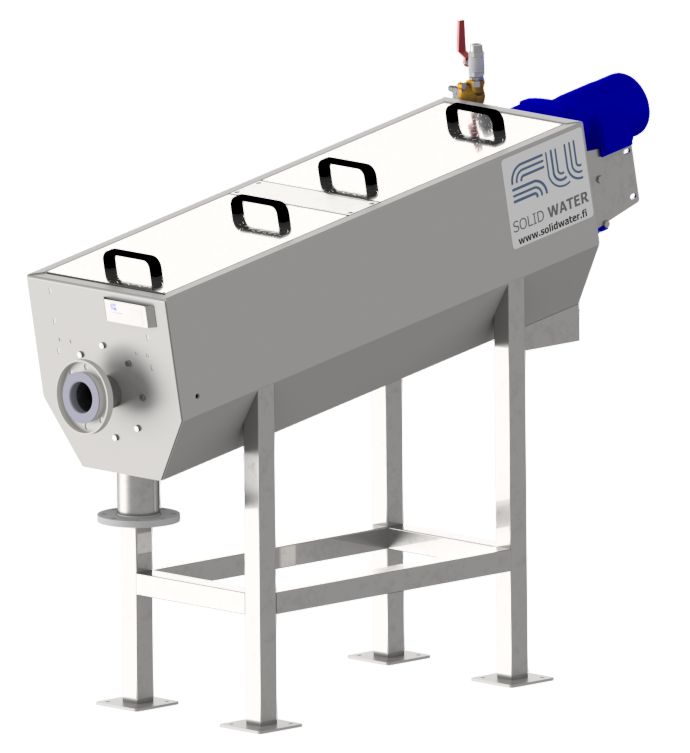

The SW flocculator is an effective and reliable polymer and sludge mixing device designed to ensure an optimal flocculation process. It consists of a sturdy tank, a precisely designed mixer, and strategic inlet and outlet connections. The adjustable mixing speed and advanced mixer design ensure uniform distribution of the mixture, thus improving flocculation efficiency.

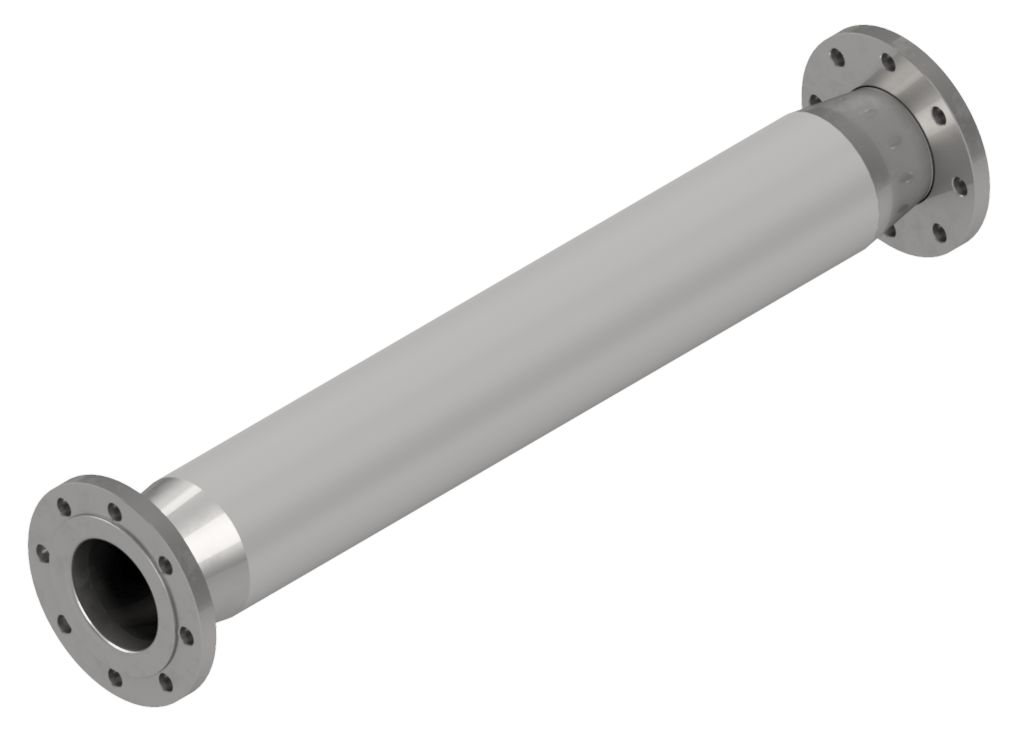

It can also be supplied as a static pipe mixer, adapted to various wastewater treatment systems. The device is made of high-quality stainless or acid-resistant steel (AISI 304, AISI 316), ensuring durability and resistance to aggressive environments.

Advantages:

- Adaptability to different flows – the mixing intensity can be adjusted according to specific process requirements.

- Resistance to aggressive media – made of AISI 304 or AISI 316 stainless steel, ensuring durability even in the most challenging conditions.

- Flexible design solutions – choose between a dynamic or static mixer according to your specific needs.

This flocculator can be easily combined with the SW belt filter press, SW drum thickener, and SW belt thickener.

How it works

SW Flocculator operating principle

The SW flocculator is designed to efficiently prepare a mixture of polymers and sludge, ensuring optimal conditions for flocculation – a process during which small particles combine into larger structures (flocs) that are easier to separate from water.

Inlet stage – the device receives the polymer solution and sludge through the inlet connections. At this stage, it is important to ensure accurate polymer dosing for effective flocculation.

Mixing process – a mixer in the tank mixes the polymers with the sludge at a controlled speed. The well-designed geometry of the mixer creates optimal flow movement, allowing the particles to distribute evenly and begin to form stable flocs.

Flocculation optimization – adjustable mixing intensity allows the process to be adapted to specific requirements without damaging the formed flocs.

Discharge – the formed flocs are evenly discharged through the discharge connection, where they can be settled, filtered, or pressed in mechanical sludge dewatering systems in the next process.

An alternative option is a static pipe mixer, in which flocculation takes place without moving parts. Here, the mixture flows through specially designed internal structures that ensure effective mixing by hydrodynamic forces.

Due to its durable construction and high-quality stainless steel (AISI 304, AISI 316), the SW flocculator is a reliable solution for wastewater treatment in various industries, ensuring an efficient and stable process.

Specification

The technical data provided in this presentation is for reference only and must be determined on a case-by-case basis. Technical changes are possible.

Application and areas of activity

SW Flocculator application cases

The SW flocculator is widely used in various areas where effective separation of solid particles from liquids is required, optimizing wastewater treatment processes. Here are some of the main areas where this device is used:

1. Industrial wastewater treatment

In many industries, production generates wastewater with high concentrations of organic and inorganic pollutants. The SW flocculator is used:

- In the food industry – to remove fats, proteins, and solid particles from wastewater from milk, beer, meat, or sugar production.

- In the paper and pulp industry – to separate cellulose fibers and organic compounds before further treatment.

- In the chemical industry – to treat wastewater containing metal ions, emulsions, or synthetic materials.

2. Municipal wastewater treatment plants

Public wastewater treatment plants use flocculation as one of the stages of sludge treatment. The SW flocculator helps to:

- Improve secondary sedimentation in biological processes.

- Reduce the amount of sludge to be recycled by optimizing filtration or sedimentation efficiency.

- Prepare sludge for more efficient mechanical dewatering (e.g., pressing, centrifuging).

3. Water treatment systems

Some sectors require not only wastewater treatment but also the production of clear water. The SW flocculator is used:

- In the preparation of drinking water, when small turbidity particles are removed from natural sources.

- Industrial water supply, where solid particles must be removed before process use.

4. Mining and metallurgical industry

Mining activities often generate large wastewater flows containing heavy metals and mineral particles. The SW flocculator helps to:

- Stabilize and bind fine particles so that they settle more easily.

- Reduce wastewater treatment costs by improving filtration efficiency.

5. Oil and gas industry

In oil refineries and drilling platforms, the SW flocculator can be used to remove emulsions, fine oil particles, and heavy compounds from wastewater, thereby improving conditions for reuse or disposal.

Additional options

An alternative option is a static pipe mixer, in which flocculation takes place without moving parts. Here, the mixture flows through specially designed internal structures that ensure effective mixing by hydrodynamic forces.