What is sewage sludge?

Sludge from wastewater treatment is an unavoidable reality in both industrial and municipal treatment plants. It is a mixture of organic and inorganic particles, rich in micro-organisms, contaminants and water. With a water content of up to 99%, effective dewatering is essential to reduce the volume of sludge, facilitate its management and ensure its sustainable use. Sludge treatment: how to choose sustainable and effective solutions?

Why treat sludge?

Untreated sludge poses serious environmental and health problems – it can give off unpleasant odours, pollute water bodies and pose sanitary risks. Ideally, no waste would be left after wastewater treatment, but the reality is different: sludge is continuously generated and its heavy metal content limits its direct use. For this reason, there is a worldwide search not only for efficient ways to treat sludge, but also for ways to turn it into a valuable product for use in agriculture, industry or energy production.

Properly treated sludge:

- It adds value – it can be used as fertiliser, burned to produce energy or recycled into other products.

- Reduces volume – lower storage and transport costs.

- Reduces pollution – fewer harmful substances are returned to the environment.

„Ideally, there would be no waste after wastewater treatment, but the reality is different: sludge is continuously generated and its heavy metal content limits its direct use.”

What are the processes used to treat sludge?

Sludge management consists of several steps, depending on the final destination: whether it is recycled, recovered or used for energy production. The ultimate goal is to obtain a stabilised, standardised sludge that can be safely reused in agriculture, burned as fuel or otherwise managed. This not only reduces waste, but also allows energy and valuable nutrients to be recovered from the materials that make up the sludge. We will look at some of the steps involved in sludge treatment:

1. Compaction of sludge. Purpose: to reduce the volume of sludge by 30-80% to facilitate handling and transport. Methods used:

- Gravitational compaction – silt settles naturally, displacing excess water.

- Mechanical compaction – drum, disc or belt compactors and centrifuges.

- Flotation compaction – air bubbles lift particles to the surface where they are collected.

2. Sludge conditioning. Purpose: chemical or biological treatment to improve sedimentation and facilitate water separation. Equipment used: polymer preparation stations, flocculators.

3. Draining the sludge. Purpose: to remove as much water as possible to make the sludge lighter and more workable, with a target dry matter concentration of 18-30 %, depending on the technology. Equipment used: belt filter presses, screw presses, centrifuges (decanters)

These plants can be fed with either compacted or liquid sludge, depending on the treatment technology of the wastewater treatment plant.

How to choose sludge dewatering equipment?

There are three main factors to consider when choosing sludge dewatering equipment:

- Sludge characteristics – different wastewater treatment plants generate different sludge compositions, so the equipment must be adapted to specific conditions.

- Process efficiency – the aim is to achieve maximum solids content with minimum energy consumption.

- Operational costs – the simpler the maintenance and lower the energy consumption, the more efficient and cost-effective the process.

Modern, automated and easy-to-maintain equipment allows you to achieve the best results by:

- Offering environmentally friendly solutions – contributing to sustainability and reducing pollution.

- Ensures efficient sludge treatment – less waste, more useful resources.

- Reduces operational costs – saves energy and ensures longevity.

What are the recommended sludge treatment plants?

Based on the above criteria, you can choose from reliable, time-tested solutions from the manufacturers we represent to help you save energy and optimise costs:

SW Polymer preparation stations and flocculators – efficiently support the sludge dehydration process, reducing electricity and polyelectrolyte consumption.

CBB Decanters (centrifuges) – efficiently separate solids from liquids, reaching 20-30% dryness, using strong centrifugal force.

SW Sludge belt filter presses – mechanical removal of water allows you to achieve 18-25% dry solids with minimal energy consumption.

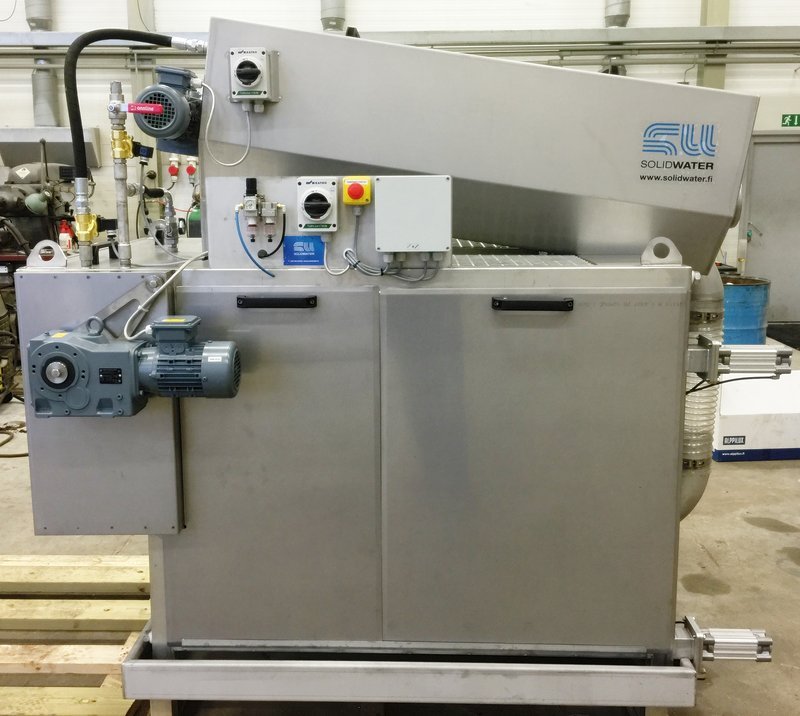

SW Belt and Drum sludge thickeners – optimal use of space, reducing the need for additional thickeners.

„Sustainability is not just about ecology or technology. It’s about long-term thinking and taking responsibility for what we leave behind. It’s also about a consistent approach, innovation and perseverance that can ensure a cleaner environment not just today, but for generations to come.”

Is sustainability just ecology?

Sustainability is not just about ecology or technology. It’s about long-term thinking and taking responsibility for what we leave behind. It’s also about a consistent approach, innovation and perseverance that can ensure a cleaner environment not just today, but for generations to come.

Modern sludge treatment technologies help to optimise processes, reduce operating costs and contribute to sustainability and environmental goals. Each municipal wastewater or industrial wastewater treatment plant has unique needs, so it is important to choose the right solution. If you are considering which technology would best meet your requirements, get in touch and together we will find the most efficient and cost-effective solution!

Contact us, because we are eager to contribute to improving your wastewater treatment processes!