Aprašymas

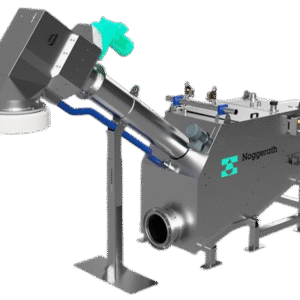

Noggerath®Būgninės Grotos RSI-DD revoliucinė nuotekų valymo technologija kanale arba konteineryje

Noggerath®Būgninės Grotos RSI-DD tai kombinuotas nuotekų valymo įrenginys kuris apjungia smulkų nuotekų sijojimą, išsijotų medžiagų transportavimą, sausinimą, sutankinimą ir pašalinimą kartu su pasirenkama papildoma plovimo zona. Priešingai nei įprastinėje technologijoje, sieto būgnas ir sraigtinis transporteris sukasi nepriklausomai vienas nuo kito, todėl įleidimo zonoje būgninis sietas gali būti be pakabinamos sukamosios svirties o tai įtakoja, kad įleidimo zona visada būna atvira ir neužsikemša.

Šie svarbūs privalumai leidžia Noggerath® būgninėms grotoms RSI-DD išsiskirti tarp kitų nuotekų valymo įrenginių ir užtikrina aukščiausią našumą bei patikimą, apibrėžtą ir tikslingą smulkių medžiagų atskyrimą, kad būtų optimizuoti tolesni nuotekų valymo procesai ir apsaugota aplinka:

Privalumai :

- Dviguba pavara be guolių.Tokia dviguba būgninių grotų RSI-DD pavara leidžia optimaliai reguliuoti būgno ir sraigto sukimosi ritmą atsižvelgiant į konkrečių nuotekų sudėtį. Tai reiškia, kad sijojamos medžiagos gali būti gabenamos į transporterio bunkerį nepriklausomai nuo bugno sukimosi ritmo. O pilnas konvejerio ištuštinimas gali būti atliekamas nepriklausomai nuo būgno darbo.

- Atvira įleidimo zona. Visiškai laisvas sijojimo plotas ypač svarbus dėl mažų srauto nuostolių, efektyvesnio kietųjų dalelių filtravimo proceso ir atliekant techninę priežiūrą.

- Kompaktiška konstrukcija. Kompaktiška konstrukcija, kurioje telpa smulkus sijojimas, išsijotų medžiagų transportavimas, sausinimas, sutankinimas kartu su papildomai pasirenkamu plovimu, užtikrina optimalų vietos panaudojimą, mažą aukštį virš viršutinio kanalo krašto, bet tuo pačiu išlaikant didelį kietųjų dalelių atskyrimo efektyvumą ir lėšų taupymą papildomai infrastruktūrai.

- Lengva techninė priežiūra, Pavaros varikliai lengvai pasiekiami, o susidėvinčios detalės suprojektuotos segmentais, leidžia lengvai keisti tik susidėvėjusias dalis. Tai užtikrina minimalų atsarginių dalių suvartojimą ir patogią techninę priežiūrą.

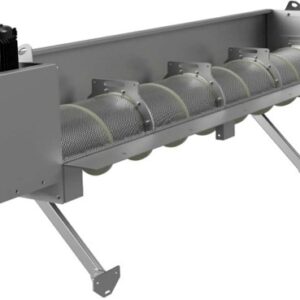

- Sraigtinis transporteris su šepetėliais. Sraigtinis transporteris su specialiais šepetėliais, prisuktais prie apatinės sraigto dalies, efektyviai valo drenažo zoną. Šepetėliai, gaminami segmentais, užtikrina lengvą priežiūrą ir keitimą.

- Ilgas tarnavimas laikas. Grotos yra gaminamos iš aukštos kokybės nerūdyjančio plieno ir apdorotos rūgštinėje vonioje, siekiant užtikirnti ilgaamžiškumą bei atsparumą agresyvioms aplinkos sąlygoms

Noggerath® Sukamosios būgninės grotos RSI-DD gali būti papildomos:

- Radial Eco Drive RED pavara, kuri yra unikali ir patentuota radialinė eko krumpliaratinė pavara.

- RSI-DD-T / RSI-DD-T-RED konteinerine versija., kuri naudojama kai nėra galimybės įrengti kanale.

Apie sėkmingą šių grotų pritaikymą skaitykite mūsų tinklaraštyje