Aprašymas

Noggerath®Vertikalus Sraigtinis Sietas NSI-V- kompaktiškas vietą taupantis sprendimas

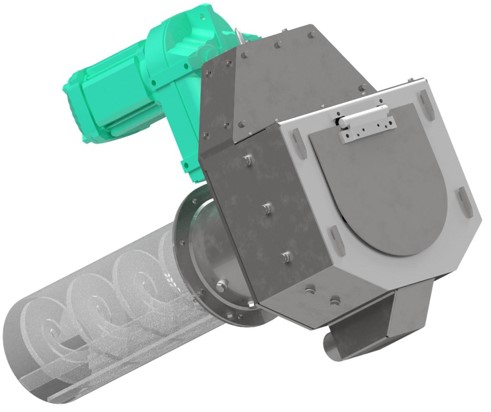

Noggerath®Vertikalus Sraigtinis Sietas NSI-V – tai neabejotinai unikalus ir lengvai pritaikomas sprendimas nuotekų tvarkymui, nuo šulinių iki galutinio nuotekų išleidimo taško.

Šis kompaktiškas įrenginys, pagamintas iš aukščiausios kokybės nerūdijančio plieno, sujungia sietą, sraigtą ir presą, suteikdamas optimalią nuotekų sijojimo patirtį ir pasižymi šiais privalumais. Vertikalus Sraigtinis Sietas NSI-V – tai sprendimas, suteikiantis jums įrankius įveikti šiuolaikinius nuotekų tvarkymo iššūkius.

Privalumai:

- Kompaktiškas, vietą taupantis dizainas. Vertikalus montavimas ir modulinis surinkimas leidžia lengvai pritaikyti įrenginį skirtingoms vietoms ir sąlygoms arba integruoti į jau esamus įrenginius. Tai sutaupo ne tik vietą, bet ir lėšas infrastruktūrai įrengti.

- Spiralinio šepečio efektyvumas. Spiralinis šepetys, sumontuotas priešingai transportavimo krypčiai, neleidžia sijojamoms medžiagoms prasiskverbti pro sietą. O segmentinė šepečio konstrukcija užtikrina greitą ir lengvą šepečio elementų keitimą bei padeda taupyti, nes galima keisti tik susidėvėjusias dalis.

- Efektyvumas ir energijos taupymas . Įrenginys viename procese atlieka smulkų sijojimą, plovimą, transportavimą, tankinimą ir sausinimą viename procese, taupant resursus ir vietą. O tiesioginė pavara su mažomis energijos sąnaudomis užtikrina efektyvų veikimą ir prisideda prie energijos taupymo.

- Lengva techninė priežiūra. Visos pagrindinės vertikalaus sieto dalys tvirtinamos varžtais, užtikrinant patogią ir lengvą techninę priežiūrą. Tai sumažina laiko ir pastangų sąnaudas, reikalingas reguliariai priežiūrai.

- Atliekų kiekio sumažinimas. Unikali sutankinimo zona leidžia sumažinti atliekas iki 60% ir išsausinti iki 35% sausos medžiagos ,priklausomai nuo kietosios medžiagos rūšies. Tai mažina atliekų kiekį ir įtaką aplinkai.