Aprašymas

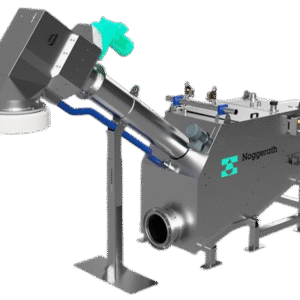

Atvežtinių nuotekų priėmimo stotelė FEKO+ yra inovatyvus ir visapusiškas nuotekų tvarkymo sprendimas.

Atvežtinių nuotekų priėmimo stotelė FEKO+ yra visiškai automatizuotas įrenginys, kuriam nereikia nuolatinio operatoriaus dalyvavimo. Stotis valdoma duomenų nuskaitymo, programavimo ir archyvavimo programine įranga, pagrįsta „Windows Embedded” operacine sistema. Nuotekų priėmimo stotys FEKO+ susidedančios iš konteinerio, pagaminto iš nerūdijančiojo plieno (viduje ir išorėje), ir programinės įrangos FEKO+ transformuoja šiuolaikinį nuotekų priėmimą.. Ji gali nustatyti nuotekų kilmę, taip pat kiekvieną vežėją. Be to, ji gali matuoti išleidžiamų nuotekų tūrį ir įvairius parametrus, pavyzdžiui, pH, temperatūrą laidumą, užtikrinant visapusišką nuotekų stebėseną. Tai padeda užtikrinti, kad į tolimesnius valymo įrenginius nepatektų nuotekos stipriai užterštos pavojingomis medžiagomis bei nuotekos su specifine tarša. Turėdama tokias galimybes, ji prisideda prie efektyvesnio ir ekologiškesnio nuotekų priėmimo ir tvarkymo.

Privalumai:

- Automatizavimas. Stotelė automatizuotai valdo atvežtinių nuotekų srautą, nuo priėmimo iki išplovimo, palengvindama tvarkymo procesus.

- Kvapų kontrolė. Greitąją jungtį naudojanti žarna užtikrina, kad kvapai neplistų į aplinką, prisidedant prie aplinkosaugos.

- Automatinis praskalavimas. Sistemos automatinis išplovimas užtikrina švarą ir pasirengimą sekančiam nuotekų priėmimui.

- Identifikacija. Programinė įranga tiksliai nustato vežėjus, vairuotojus ir nuotekų šaltinį, užtikrinant tikslų duomenų surinkimą.

- Parametrų matavimas. Stotelė realiu laiku matuoja ir registruoja nuotekų parametrus, įskaitant pH, temperatūrą ir kitus..

- Duomenų tvarkymas. Ji suteikia galimybę kurti išsamias duomenų bazes, optimizuojant sprendimus ir suteikiant kontekstą apie rangovus, tiekėjus ir vietoves.

- Įrašų saugojimas. Galimybė įrašyti visus pristatymo duomenis ir perkelti juos į atminties kortelę, užtikrina duomenų saugumą ir pasiekiamumą..

- Duomenų eksportavimas. Eksportuojant surinktus duomenis į įvairius failų formatus, suteikiama galimybė dalintis ir naudoti informacija patogiai.

- Nuotekų parametrų kvitas: Stotelė automatiškai generuoja ir spausdina priėmimo kvitus su visais būtinais parametrais, užtikrindama patikimą dokumentaciją ir reikalavimų laikymąsi.

- Pirminis valymas. Su mechaninėmis grotomis (sietu), kurių protarpių dydis pritaikomas pagal užsakovo reikalavimus, bei nešmenų smulkintuvu (moceratoriumi), vyksta pirminis nešmenų apdorojimas, užtikrindamas sklandų tolimesnį nuotekų apdorojimą.

Atsižvelgiant į jūsų poreikius ir priimamų nuotekų sudėtį bei kiekį, bus parenkami atitinkami stoties komponentai, kurie turės įtakos konteinerio, kuriame bus įrengta FEKO+ stotis, dydžiui.

Atvežtinių nuotekų priėmimo stotelė FEKO+ yra septynių pagrindinių dydžių – nuo FEKO+/SX dėžės modelio iki FEKO+/XXL konteinerio, kuriame galima įrengti smėlio gaudyklę. Visuose konteineriuose įrengta elektrinė šildymo sistema su radiatoriumi, mechaninis vėdinimas ir apšvietimas.

FEKO+/TO gali būti visų pateiktų išnatavimų tik plius tai yra stoties modelis, skirtas riebalams ir nuotekų dumblui priimti. Nuo standartinės stoties skiriasi debitmačio matavimo elektrodų tipu. Joje naudojami kūginiai elektrodai, kurie savaime išsivalo atliekų išleidimo metu.

FEKO+ BUD yra panašus stoties modelis, tačiau be išorinio konteinerio.

Kaip tai veikia

FEKO+ atvežtinių nuotekų stotelė veikia visiškai automatizuotai, užtikrindama efektyvų nuotekų priėmimą ir tvarkymą be nuolatinio operatoriaus įsikišimo. Šią sistemą valdo speciali programinė įranga, paremta „Windows Embedded“ operacine sistema, kuri sukuria optimalias sąlygas veikimui, Stotelei pakanka tik periodinės techninės priežiūros, suteikiant vartotojui paprastumą ir patikimumą.

Vairuotas atvežęs nuotekas, prijungęs cisterną su nuotekomis prie FEKO+ konteinerio, pasinaudoja RFid raktu identifikuodamas save. Tuomet naudodamasis LCD ekranu, įveda informaciją apie atvežtų nuotekų kilmę. Unikali vairuotojo identifikavimo sistema nustato vežėją, o sklendė, valdoma pneumatine/elektrine pavara, atsiveria. Per pajungimo žarnas ir debito matuoklį nuotekos nukreipiamos į mechanines grotas arba smulkintuvą, kur vyksta nešmenų apdorojimas.

Kai nuotekos pasiekia matavimo indą, sistema automatiškai matuoja svarbiausius parametrus, įskaitant pH, temperatūrą ir kitus. Jei nuotekos neatitinka nustatytų programoje parametrų, įsijungia automatinė sklendė, užkertanti kelią netinkamų nuotekų patekimui į valymo sistemą. Šis funkcionalumas užtikrina, kad atvežtos nuotekos visada atitiktų numatytus standartus ir būtų tinkamos tolimesniam tvarkymui.

Baigus nuotekų išleidimą, vairuotojui išduodamas kvitas su kiekiais ir parametrais, o visi šie duomenys saugomi programinėje įrangoje. Tai ne tik leidžia atlikti duomenų analizę, bet ir optimizuoti procesus, užtikrinant skaidrumą bei patikimumą nuotekų valdymo sistemoje.

FEKO+ valdymo spintos sudėtyje yra :

- 7 arba10 colių spalvotas LCD jutiklinis ekranas.

- Valdymo sistema su duomenų archyvavimu ir galimybe sukurti duomenų bazę.

- Programinė įranga, pagrįsta „Windows Embedded“

- Vidinė atmintis (miestai, adresai )

- Eterneto arba belaidžio (Wi-Fi) ryšio modulis. Kontaktuoja su programine įranga

- USB įvestis duomenų perdavimui ir rankiniam stotelės programavimui.

- MOBUS RTU/TCP arba „Profibus“ ryšio protokolas.

- Vežėjo identifikavimo modulis- RFiD raktų žiedai.

- Nuotekų tipą identifikuojantis modulis.

- Modulinis spausdintuvas su popieriaus pjaustytuvu.

- Pramoninė klaviatūra ( pagaminta iš nerūdijančio plieno ).

Su FEKO+ programinė įranga galėsite:

- Nuotoliniu būdu valdyti FEKO+ stotelę,

- Rengti ataskaitas pagal FEKO+ stotelės perduodamus duomenis,

- Nustatyti stotelės parametrus,

- Sugeneruoti ir išrašyti sąskaitas faktūras bei kurti paradavimų registrus,

- Atlikti daugelį kitų prietaisui eksploatuoti reikalingų funkcijų,

- Nuotoliniu būdu atnaujinti programinę įrangą,

- Sukurti obektų, kuriuose įrengti septikai, duomenų bazę su galimybe juos sugrupuoti į gyvenamuosius rajonus ar vietoves,

- Planuoti vežėjų patikrinimus,

- Atlikti statistinę duomenų analizę su automatine neatitikimų ataskaitų generavimo funkcija, pvz., apie objektus, iš kurių buvo pristatyta mažiau / daugiau nuotekų, nei buvo numatyta.

Specifikacija

Konstrukcijos variantai :

- Konteinerių vidinės ir išorinės sienos pagamintos iš nerūdijančio plieno sluoksnių sumuštinio tipo plokščių su 100 mm izoliacija.

- Nerūdijančio plieno vamzdynas 0H18N9 su matavimo indu

- Grindys iš raižytos aliuminio plokštės

- Mechaninė ventiliacija

- Srauto matuoklis ir pasirinkti rinkiniai fizikiniams ir cheminiams matavimams Endress+Hauser

- Feko+ išorinė spintelė su valdymo ir identifikavimo skydeliu

|

Plotis (mm) |

Aukštis (mm) |

Gylis(mm) |

| FEKO+ XS |

800 |

900 |

1800 |

| FEKO+ S |

1000 |

2300 |

2000 |

| FEKO+ M |

1400 |

2300 |

2400 |

| FEKO+ ML |

2400 |

2600 |

2400 |

| FEKO+ L |

2400 |

2600 |

3600 |

| FEKO+ XL |

4200 |

2600 |

2400 |

| FEKO+XXL |

3400 |

2600 |

6400 |

| FEKO+ TO |

FEKO+/TO gali būti visų pateiktų išnatavimų tik plius tai yra stoties modelis, skirtas riebalams ir nuotekų dumblui priimti. Nuo standartinės stoties skiriasi debitmačio matavimo elektrodų tipu. Joje naudojami kūginiai elektrodai, kurie savaime išsivalo atliekų išleidimo metu. |

| FEKO+ BUD |

FEKO+ BUD yra analogiškas stoties modelis, tik be išorinio konteinerio. Visa technologinė įranga bus sumontuota esamoje patalpoje ir neturi jokių apribojimų įrengtų kanalizacijos linijų skaičiui.

|

| ML, L / XL ir XXL |

ML, L / XL ir XXL versijų nuotekų priėmimo stotys leidžia įrengti dvi nepriklausomas išleidimo linijas. |

Šiame pristatyme pateikti techniniai duomenys yra tik orientaciniai ir turi būti nustatomi kiekvienu konkrečiu atveju. Galimi techniniai pakeitimai

Papildomos parinktys

Stoteles galima rinktis įvairių dydžių ir komplektacijos:

Feko+XS, Feko+S, Feko+M, Feko+ML, Feko+L, Feko+XL, Feko+XXL

- Srauto matavimo įrenginys,

- Drenažo linija,

- Matavimo indas,

- Identifikatoriai,

- Pneumatinė arba elektrinė uždaromoji sklendė,

- Kompresorius,

- Sustiprinta jungiamoji žarna,

- Užterštumo matavimo rinkinys (pagrįstas „Memosens“ sistema),

- Mechaninės grotos (sietas), kurių protarpių dydis pritaikomas pagal užsakovo reikalavimus,

- Sraigtinis nešmenų presas,

- Uždara sulaikytų nešmenų šalinimo sistema į konteinerį,

- Smulkintuvas (Maceratorius),

- Akmenų gaudyklė,

- Automatinio praskalavimo sistema,

- Stacionarus mėginių ėmiklis,