Description

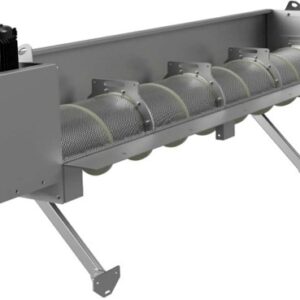

Passavant® Multi-Rake Bar Screen KUR is a high efficient revolving chain screen and suitable for both coarse and fine screening.

Passavant® Multi-Rake Bar Screen KUR is the most reliable pre-treatment of wastewater and are definitely the perfect solution for those who want efficient wastewater treatment and the protection of downstream treatment processes. In addition to providing long-term reliable performance, these screen also offer the following advantage.

Benefits:

- Very short cleaning cycle. Several rotating cleaning elements (comb plates) and additional cleaning elements, which can be easily installed if required, ensure efficient cleaning in a shorter cleaning cycle.

- High cleaning performance. Thanks to the reduced bar spacing and the innovative teeth of the rake combs, the flow-friendly bar profile and the curved bar segments at the bottom of the channel, the KUR bar grating guarantees a high cleaning performance.

- Precise connection of the cleaning elements. The additional levelling guide system with double wheels ensures precise coupling and movement of the rake comb plate to prevent the loaded debris plates from shifting.

- Lower guide parts. Thanks to the plastic and stainless steel lower guides attached to the side frame, these grilles are low maintenance and low wear.

- Robust and compact design These bar grilles do not require a high installation height above ground level, and the highly stable frame structure, thanks to the centrally positioned circular profiles with easily replaceable parts, provides flexibility and ensures long-lasting use.

- Optimised production and easy installation. Laser cutting and 3D folding technology allow for piecemeal or complete assembly. The grilles can therefore be easily adapted to different areas while maintaining high quality.

- Low maintenance, low wear and tear. Thanks to the easy replacement of the gear teeth without removing the chains (except for KUR-DEFENDER), to the non-submersible bearings and gears, and to the maintenance-free stainless steel roller chain, these grilles require minimum maintenance and save money.

- Innovative solutions. Curved bar profiles, reverse operation, swivel chain box (KUR-S), individually controlled chains are just a few of the innovative features that set these grilles apart.

- Reliability. Thanks to in-house production and modern warehousing, the availability of spare parts and short delivery times are guaranteed for many years.

- Security. The grilles are equipped with electrical protection and an overload alarm to ensure the protection of the unit and uninterrupted operation.

Passavant® Multi-Rake Bar Screen KUR – available in the following versions:

- KUR-HD – Heavy Duty version for particularly demanding applications involving deep channels and large volumes of debris (for channels up to 6 m wide).

- KUR-C – Standard solution suitable for up to 3 m wide channels

- KUR-S – With swivel chain guide and bar rack, across the full width of the channel, for smaller channels up to 2 m long. KUR-S: Swivel chain box for maintenance and obstruction avoidance.

- KUR-D DEFENDER – Compact standard version with flat profile bars.