Description

Noggerath® OVF and OVF-R – reliable overflow screens for rainwater and mixed wastewater filtration

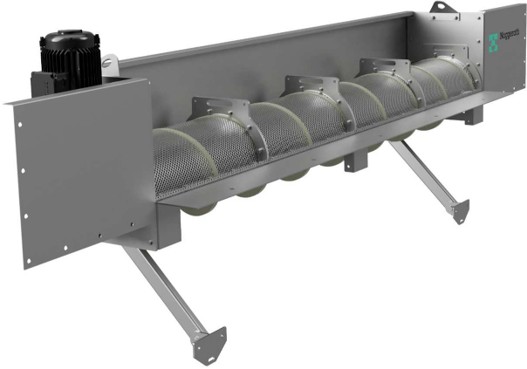

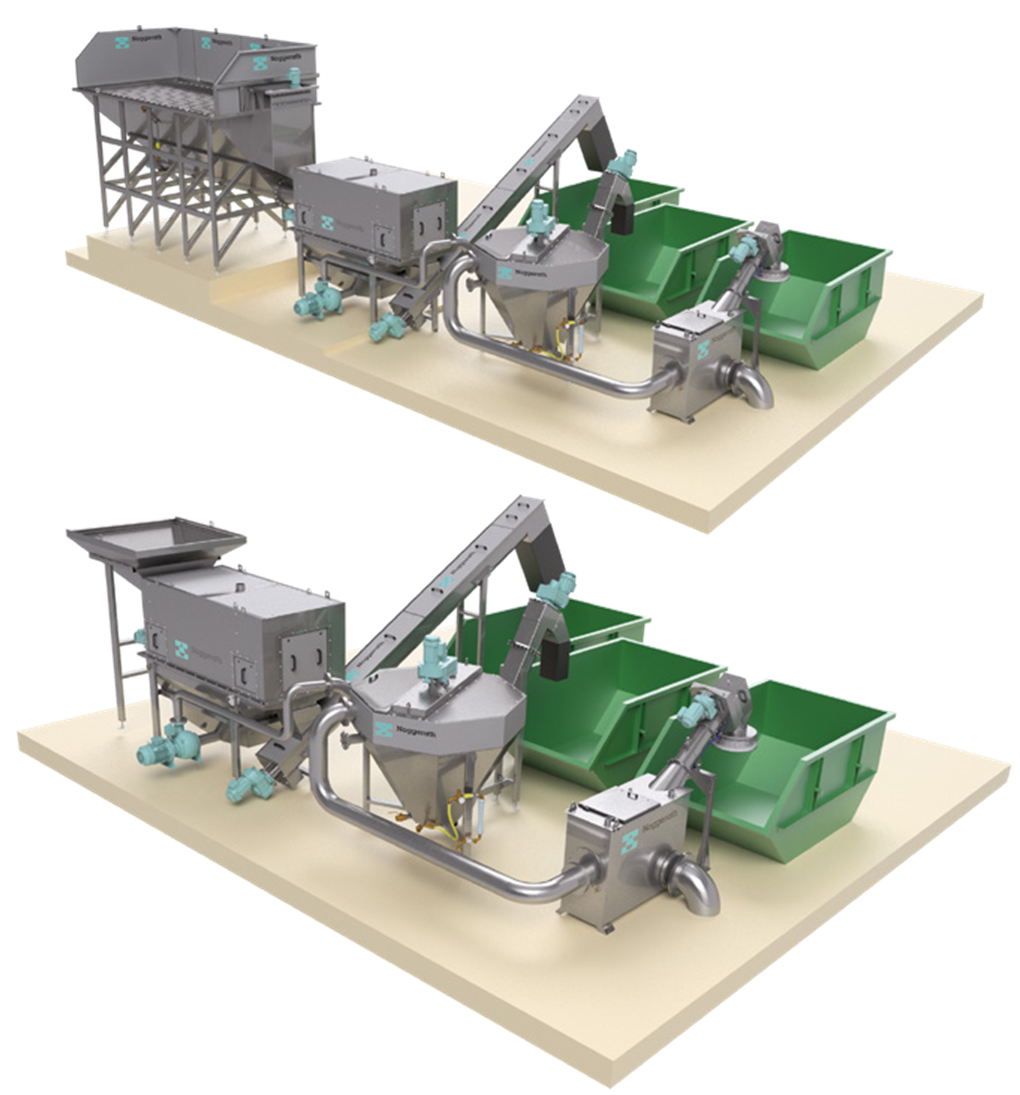

Noggerath® OVF and OVF-R overflow screens are efficient and reliable overflow screens designed to filter rainwater and mixed wastewater flows at high flow rates. They belong to the screw screen family and are designed for the automatic separation of coarse impurities from wastewater when systems are subjected to high loads – e.g. during heavy rainfall, mixed wastewater overflows or plant malfunctions.

Each screen consists of a semi-cylindrical perforated screen with an integrated cleaning and transport screw inside. This design allows the system to operate efficiently, reliably, and without additional operator intervention. OVF and OVF-R screens are widely used in both municipal and industrial wastewater treatment plants, where it is important to protect both water bodies and internal processes from large contaminants.

Advantages:

- Effective even at high flow rates – extremely low hydraulic resistance, so the screen quickly passes the flow without losing filtration efficiency.

- No clogging – reliably retains large particles and gently transports them with a screw mechanism.

- Automatic cleaning – a spiral brush continuously cleans the radial screen surface, ensuring flawless operation.

- Easy maintenance – brushes are replaced individually as they are attached with screws – only worn parts are replaced.

- Easy integration – can be installed in existing infrastructures without major structural changes.

- No technical water required – lower operating costs and simpler management.

Noggerath® Overflow Screens OVF and OVF-R – a solution that works exactly when you need it most.

How it works

OVF operating principle

Wastewater flows vertically through the screen surface from top to bottom, and solids are effectively retained on the inner side of the screen.

When the water level upstream of the screen rises to a predetermined limit, the screw conveyor drive is automatically activated.

The accumulated solids are gently transported by the screw to the discharge area. They can be returned to the wastewater stream or, optionally, removed for further treatment.

A cleaning brush mounted against the direction of the screw movement continuously cleans the radial screen surface, ensuring effective filtration and preventing clogging.

When the upstream water level drops below the set limit, the conveyor drive is automatically switched off.

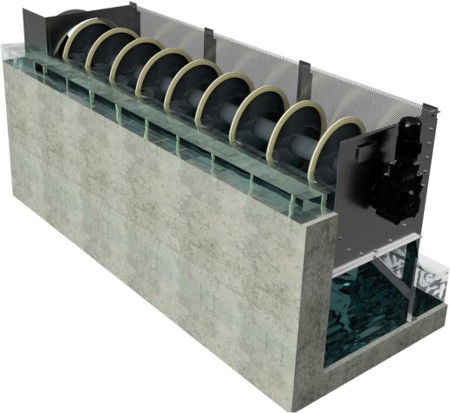

OVF–R operating principle

Wastewater flows vertically from bottom to top through the screen.

Solid particles are effectively retained on the inner side of the screen.

When the water level upstream of the screen rises to a set limit, the screw conveyor drive is automatically activated. The accumulated solids are gently transported by the screw to the discharge area and returned to the wastewater stream.

A cleaning brush mounted against the direction of the screw movement continuously cleans the radial screen surface, preventing clogging and ensuring efficient filtration.

Specification

Model name: indicates the approximate diameter and length of the trough, e.g., OVF 500-2500 means a sieve with a diameter of 500 mm and a length of 2.5 m.

| OVF ir OVF-R |

300 |

500 |

700 |

1000 |

| Screen trough diameter {mm} |

310 |

512 |

717 |

1016

|

| Screen hole diameter {mm} |

3-10

|

| Gear unit {kW} 400V / 50Hz (depending on length) |

0,55 / 0,75 |

0,75 / 1,1 |

0,75 / 1,5 |

1,5 / 3

|

|

Width {mm}

|

470 |

1020 |

1160 |

1300

|

|

Spiral diameter {mm}

|

300 |

500 |

705 |

970

|

| Brush diameter {mm} |

310 |

512 |

717 |

1020

|

| Length {mm} |

1-10 (kiti pagal pageidavimą)

|

| Flow [m³/h] 1m sieve trough length |

Iki 1600

|

All components are made of durable and corrosion-resistant materials suitable for use in wastewater treatment plants. Some parts can be customized to individual requirements.

| Components |

Material |

| Screen trough, frame, support |

Stainless steel AISI 316L (1.4404) or AISI 304 (1.4301). Others on request |

| Screw |

Special microalloy steel (carbon steel) or stainless steel AISI 316L (1.4404) or AISI 304 (1.4301) |

| Connecting parts |

Brass or stainless steel |

| Cleaning brushes |

Polyethylene body, nylon brush, or stainless steel |

The technical data provided in this presentation is for reference only and must be determined on a case-by-case basis. Technical changes are possible.