Description

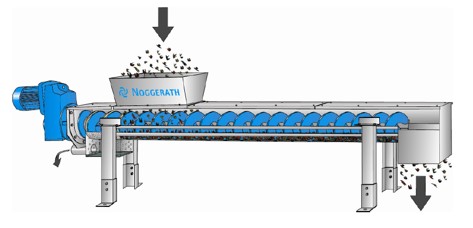

The Noggerath® Screw Conveyor SC is distinguished by its unique shaftless spiral design

This spiral operates in a U-shaped chute with a replaceable abrasion-resistant coating, ensuring reliable, obstruction-free material movement. The size, length and mounting angle of this conveyor are optimally adapted to individual site requirements, giving businesses great flexibility. The Noggerath® Screw Conveyor SC has been successfully used for many years in a wide range of industries and wastewater treatment plants around the world.

Benefits

- High operational reliability. The unique design of the shaftless spiral with no internal bearings reduces the risk of blockages even with fibrous materials, ensuring long-lasting and reliable plant operation.

- Simple operation and maintenance. Thanks to the single conveying element and the long service life of the parts, the conveyor is easy to maintain with low maintenance costs.

- Long service life. The flexible, shaftless spiral guarantees a long and reliable operation of the unit, as the weight is evenly distributed over the entire length and the anti-wear liner protects the structure from damage.

- Flexible installation and integration. The unit can be easily integrated into existing installations, and a wide range of mounting options allows the conveyor to be adapted to different site conditions and requirements.

- Clog-free transport. The unique spiral design, which eliminates the need for intermediate and end supports, allows the most complex materials (dry, wet, viscous, sticky, sticky, dusty, bulky or abrasive materials) to be conveyed without any disruption, ensuring continuous and efficient material transport.

- High productivity and lower energy consumption. This Noggerath® Screw Conveyor SCoffers high productivity and energy efficiency compared to traditional roller screws.

- Pressurised system. The fully encapsulated design ensures that materials are safely transported without any loss or contamination.

- Wide range of applications. The spiral can be supplied in lengths of up to 30 metres while maintaining transport efficiency over the entire length. Horizontal, inclined and vertical mounting or combined mounting, double spiral conveyor, rotating or reversible conveyor design are also available. This offers exceptional possibilities for customising the installation to suit different needs and conditions.