Description

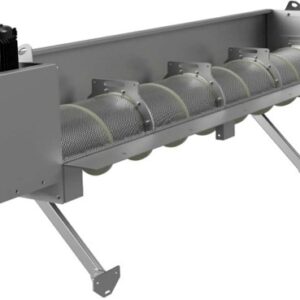

The Noggerath® NSI spiral sieve is the ultimate solution for fine sieving.

The Noggerath® NSI spiral sieve can perform the most important functions of wastewater treatment: screening, conveying, dewatering, compaction (NSI/D version ) and disposal using a perforated or wire mesh basket. The main advantages are the minimal blockage due to the shaftless screw and the spiral brush mounted in the opposite direction to the conveying direction, which prevents the passage of materials through the screen.

Benefits

- Easy integration. Its versatility and compactness make it easy to integrate into existing installations to meet local specifications and maximise the use of available resources.

- Unique brush. The spiral design of the brushes prevents materials from passing through the screen, while the easily replaceable brush segments save maintenance time and resources.

- High retention rate. The NSI/D sieve tested by the National Grating Evaluation Centre has a high retention rate (72% with 3 mm perforation, 52% with 6 mm perforation).

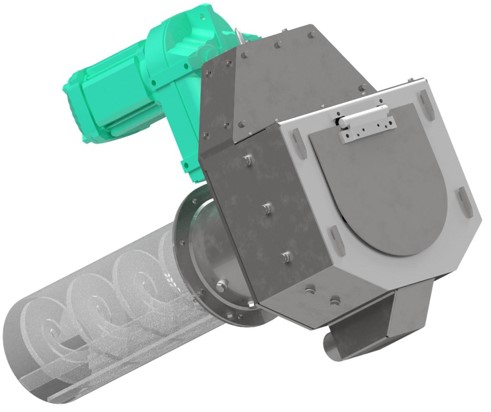

- Energy saving. Installed at an angle of 35°, this sieve ensures more efficient separation of debris, while the direct drive ensures optimum performance and reduces energy consumption.

- Durability and resistance. The sieve parts and structures are made of high quality stainless steel, treated in an acid bath, ensuring a long service life and resistance to aggressive environmental conditions.

- Noggerath® Eco Drive RED. This drive version ensures maximum efficiency and safety by eliminating the need to manually remove the sifted material accumulated in the removal zone.

- Screw sieve in NSI/D-T container. The unit can be placed in a container with flanged connections without the need for a channel.

It is a cost-effective, compact and reliable solution for wastewater management.

How it works

Effluent enters the grate basket’s inner surface directly from the channel or tank, which is open on the entry side. Initially, solid particles accumulate on the basket’s surface, forming a barrier that impedes the liquid’s free passage through the screen, causing the liquid level to rise gradually. The liquid level is monitored by an upstream level sensor. Once the level hits or surpasses a predetermined maximum, the conveyor drive starts automatically. A spiral brush, attached to the screw in the opposite direction of conveyance, cleans the bag’s surface effectively. This brush not only prevents clogging of the openings but also elevates the solids to the screw conveyor. The collected materials are then conveyed by the rotating screw to the discharge unit, where they can be drained and compressed in the compaction zone (NSI/D). The screw conveyor stops automatically when the liquid level falls below a certain point, preparing the system for the next cycle. This process ensures a continuous and uninterrupted flow in wastewater treatment.

Specification

| Forma

sieto anga |

Sieto anga |

Debitas Q pagal dydį |

| 200 |

300 |

400 |

500 |

600 |

700 |

|

mm |

l/s |

l/s |

l/s |

l/s |

l/s |

l/s |

| Perforuota plokštė |

7 |

50 |

56 |

102 |

133 |

186 |

297 |

| 6 |

45 |

50 |

88 |

120 |

174 |

285 |

| 5 |

40 |

44 |

75 |

110 |

165 |

270 |

| 3 |

28 |

35 |

50 |

90 |

130 |

208 |

| 2 |

24 |

28 |

42 |

88 |

117 |

186 |

| Vielinis tinklas |

1 |

14 |

25 |

36 |

75 |

100 |

147 |

| 0,5 |

13 |

17 |

25 |

54 |

78 |

103 |

| 0,25 |

6 |

10 |

15 |

36 |

56 |

80 |

| Vandens lygis prieš srovę ho maks. [mm] |

400 |

435 |

460 |

570 |

680 |

800 |

| Komponentai |

Medžiagos |

| Rezervuaras, krepšys, rėmas ir laikiklis

|

Nerūdijantis plienas AISI 304 arba AISI 316 Kiti pagal pageidavimą |

| Sraigtas |

Specialus mikrolegiruotasis plienas St52 (pagal AS grupės standartą), arba nerūdijantis plienas AISI 304 arba AISI 316 |

| Valymo šepečiai

|

Korpuas iš polietileno, šepetys iš nailono |

| Šoninė sandarinimo juostelė

|

Sustiprinta guma |

| Jungiamosios detalės |

Žalvaris arba nerūdyjantis plienas |

Šiame pristatyme pateikti techniniai duomenys yra tik orientaciniai ir turi būti nustatomi kiekvienu konkrečiu atveju. Galimi techniniai pakeitimai