Aprašymas

Noggerath®Combi TOP – parengtinis ir kompleksinis nuotekų tvarkymas

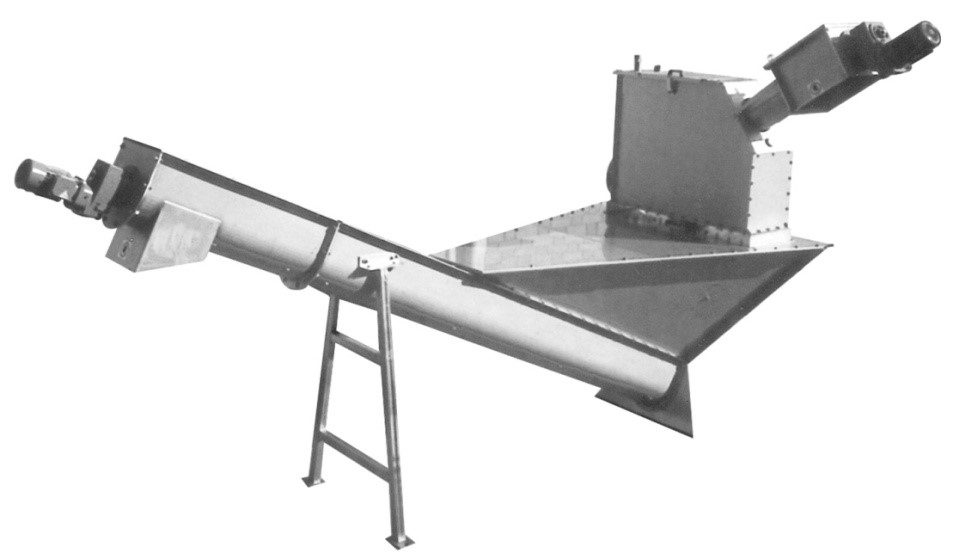

Noggerath®Combi TOP ir Combi TOP/F – tai inovatyvūs parengtinio nuotekų valymo įrenginiai, kurie gali būti sukonfigūruoti su skirtingais sijojimo procesais, įskaitant strypines grotas, smulkiuosius sietus ir būgninius sietus. Be to pasirinkti sietai arba smėlio plovimo įrenginiai gali būti integruoti į visiškai hermetišką konstrukciją, užtikrinant optimalų veikimą. Unikali išleidimo jungtis su slenksčiu užtikrina pastovų lygį rezervuare,garantuojant tinkamą žvyro nusėdimą bei efektyvų RAT pašalinimą, net esant mažam nuotekų srautui. Taip pat jie gali būti naudojami dumblui ir septiniui dumblui sijoti.

Noggerath®Combi TOP tai ne tik efektyvus, bet ir inovatyvus sprendimas, kuris užtikrina aukštą valymo standartą ir suteikia dar daug privalumų. Šie privalumai leidžia TOP ir TOP-F parengtinio valymo sistemoms tapti patrauklia alternatyva kitiems nuotekų valymo įrangos variantams, išlaikant aukštus kokybės, patikimumo ir higienos standartus bei suteikti ekonominį pranašumą.

Privalumai:

- Nereikia daug vietos. Visi mechaninio apdorojimo procesai vyksta vienoje sistemoje, todėl nereikia daug vietos įrenginio sumontavimui ir naudojimui. Tai ypač naudinga vietose, kur erdvė ribota, nes leidžia efektyviai išnaudoti turimą plotą ir sumažina statybos laiką ir sąnaudas

- Nedideli reikalavimai statyboms. Įrenginys atlieka trijų įrenginių darbą viename, todėl nereikia sumontuoti ir sujungti trijų atskirų įrenginių . Jis suprojektuotas ir sukonstruotas taip, kad sumontavimas būtų lengvas ir greitas. Tai taupo laiką ir darbo jėgos išteklius.

- Didelės pritaikymo galimybės. Galima rinktis įvairių dydžių konstrukcijas, įvairių tipų sietus, įvairius mechaninius priedus, pritaikytas smėlio gaudykles, išsijotų medžiagų plovimo įrenginius ir presus, transporterius. Su tokiomis pasirinkimo galimybėmis Combi TOP galima sukonfigūruoti pagal jūsų reikalvimus ir specifikacijas. Juos lengva pritaikyti senoms valyklom ir naujoms statyboms ir valyti nuotekas pačiu efektyviausiu būdu.

- Tvirta ir patikima konstrukcija. Įrenginio konstrukcija pagaminta iš aukščiausios kokybės nerūdyjančio plieno ir su papildomu apdirbimu ir lengvai keičiamomis dalimis, kas užtikrina lengvą techninę priežiūrą ir ilgaamžiškumą.

- Nėra guolių, besiliečiančių su nuotekomis. Įrenginys sukonstruotas taip, kad nėra guolių, kurie liestųsi su nuotekomis ir galėtų būtų pažeisti ar greičiau susidėvėtų dėl sąlyčio su nuotekomis. Tai prailgina guolių tarnavimo laiką ir sumažina priežiūros išlaidas.

- Aukšta kokybė, patikimumas už prienamą kainą. Šis įrenginys sujungia kokybę, efektyvumą ir patikimumą su patrauklia kaina, todėl suteikia naudotojams galimybę pasiekti efektyvų nuotekų valymo rezultatą be didelių investicijų.

- Riebalų šalinimas nepriklausomai nuo vandens lygio. Išleidimo jungties konstrukcija leidžia riebalų šalinimui vykti nepriklausomai nuo vandens lygio.Tai padidina įrenginio efektyvumą ir užtikrina nuolatinį riebalų šalinimo procesą, nepriklausomai nuo aplinkos sąlygų.

- Visapusiškas nuotekų tvarkymas. Įrenginyje efektyviai atskiriamos sijojamosios, nusodinamosios ir pludūriuojančios nuotekose esančios medžiagos.Tai leidžia geriau tvarkyti nuotekas ir sumažinti teršalų išsiskyrimo į aplinką riziką.

- Ilgaamžiškumas ir patikimumas. Daugelį metų užtikrinamas atsarginių dalių prieinamumas ir trumpas pristatymo laikas dėl vidinės gamybos ir modernaus sandėliavimo.

Daugiau apie Noggerath® Combi TOP ir efektyvų parengtinį valymą galite sužinoti čia