Description

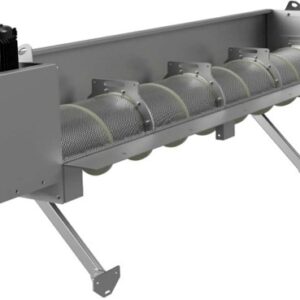

The Noggerath® wash press NWP is a simple, versatile and easily adaptable washing press

The Noggerath® wash press NWP is a reliable unit designed to effectively meet the challenges of municipal and industrial wastewater treatment in combination with pre-treatment screens and grates. It includes transport, dewatering, washing, compaction and safe disposal of the treated material. They are not only environmentally friendly, but also an economical and cost-saving way to handle sieved materials.

Benefits

- Reduction of operating costs. Replacement wear profiles in the press area and a screw made of wear-resistant special steel reduce wear and operating costs.

- Ease of maintenance. The modular design and good accessibility to all parts ensure that maintenance is easy and efficient.

- Efficient drainage. Direct contact between the auger and the slotted bottom of the drainage area ensures efficient, clog-free drainage.

- Best drainage performance. The adaptable drainage bottom and the extended feed zone allow the best possible drainage performance, adapting to local conditions.

- Re-use of organic material. Leached organic matter can be recycled back into the downstream process to maintain denitrification and improve environmental protection.

- Flexibility and adaptability. Thanks to their modular design, these scrubbing presses are easily adaptable not only to new projects but can also be integrated into existing wastewater treatment plants.

- Efficiency and sustainability. Up to 80% reduction in the weight of untreated waste and up to 45% reduction in the dry solids content of the sieved material ensure that the discharged materials meet high environmental standards.

The Noggerath® wash press NWP can be equipped with the following options

- NWP/ NSP-FF– Standard design, feed and press zone bottom made of flat profile with elongated meshes for coarse and fine screening (>2 mm) with normal water content in the screening medium.

- NWP/ NSP-PF– Inlet zone with perforated sieve bottom and pressing zone made of flat profile bottom with elongated meshes for fine screening (>2 mm ≤10 mm) and higher water content in the screening medium.

- NWP/ NSP-PW – Feed zone with perforated screen bottom and press zone with wedge wire screen bottom for fine screening (<=2) with low water content in the screening medium.