Description

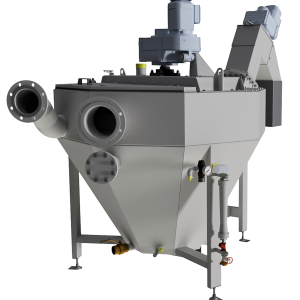

Noggerath® Grit Classifier GS excellent separation results in the separation of heavy substances from different industrial process water circuits.

The Noggerath® Grit Classifier GS has been an integral part of both municipal and industrial wastewater treatment plants for many years. Its use to separate grit or other settleable substances from liquids for the recovery of recyclable materials. And to prevent deposits and malfunctions in subsequent operation. The advantages of this Grit Classifier provide a comprehensive view of its functionality and benefits when it comes to efficient sand separation, cost reduction and environmental protection:

Benefits:

- High quality and reliability at an affordable price.

- Low maintenance thanks to simple and robust stainless steel construction.

- High operational reliability – no clogging.

- Low operating costs due to direct drive with low energy consumption.

- Low wear due to low rotational speed.

- High particulate collection efficiency.

This Grit Classifier is not only a reliable solution for the separation of grit and other sedimentary materials. It also gives you the peace of mind of further efficiency in the wastewater treatment process and a better result with less energy consumption.

How it works

The sand/water mixture is pumped into the settling tank of the sand trap. The flow is optimally directed during feeding to ensure effective separation of sediment and floating material. The inlet area of the grit chamber is designed to reduce turbulence, which adversely affects the separation process. Due to the angle of inclination of the walls of the settling tank, the sinking materials are directed onto a spiral conveyor and lifted towards the discharge outlet. The separated sand and solids are discharged into a container or into bags

Specification

Plant sizes and capacities

| Type |

GS 30 |

GS 80 |

GS 100 |

GS 130 |

| Max. Flow rate |

30 m³/h |

80 m³/h |

100 m³/h |

130 m³/h |

| Max. sand separation |

1.10 m³/h |

1.10 m³/h |

1.10 m³/h |

1.10 m³/h |

| Discharge height |

1.550 mm |

2.000 mm |

2.220 mm |

2.600 mm |

| Water top width |

2.42 m³ |

4.08 m³ |

4.08 m³ |

4.08 m³ |

| Water volume |

0.8 m³ |

1.8 m³ |

3.4 m³ |

3.7 m³ |

| Sand separation effect (. > 0.2 mm) |

90 % |

90 % |

90 % |

90 % |

| Drainage efficiency |

80 % |

80 % |

80 % |

80 % |

| Components |

Materials |

| Sand washing tank, outlet, support |

Stainless steel AISI 304 (1.4301) or AISI 316L (1.4404)

Others on request |

| Protective strips on the casing |

Hardox and stainless steel AISI 304 (1.4301) or AISI 316L (1.4404) |

| Screw |

Special micro-alloyed steel (carbon steel) or stainless steel AISI 316L (1.4404) or 304 (1.4301) |

The technical data provided in this presentation are indicative only and must be determined on a case-by-case basis. Technical changes may occur