Aprašymas

Noggerath®Sraigtinis Transporteris SC – efektyvus nešmenų transportavimas ir pritaikymas

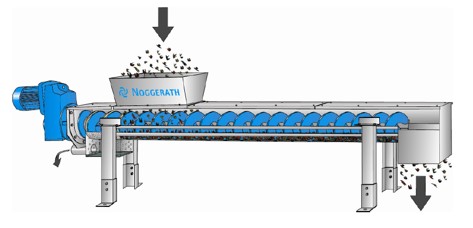

Noggerath®Sraigtinis Transporteris SC išsiskiria unikalia spiralės be veleno konstrukcija, kuri juda U formos latake ant keičiamos dilimo dangos ir užtikrina patikimą medžiagų transportavimą be užsikimšimo.

Šio transportavimo įrenginio dydis, ilgis ir montavimo kampas gali būti optimaliai pritaikomi individualiems vietos reikalavimams. Tai suteikia verslui didelį lankstumą. prisitaikant prie skirtingų poreikių ir sąlygų. Jau daugelį metų šis sraigtinis transporteris SC sėkmingai naudojamas įvairiose pramonės srityse ir nuotekų valymo įrenginiuose visame pasaulyje.

Privalumai:

- Didelis eksploatacinis patikimumas. Unikali spiralės be veleno ir be vidinių guolių konstrukcija mažina užsikimšimo riziką net su pluoštinėmis medžiagomis, užtikrinant ilgalaikį ir patikimą įrenginio veikimą.

- Paprastas valdymas ir techninė priežiūra. Dėl vieno transportavimo elemento ir ilgo detalių tarnavimo laiko, transporteris yra lengvai prižiūrimas su mažomis techninės priežiūros išlaidomis.

- Ilgas tarnavimo laikas. Lanksti spiralė be veleno, garantuoja ilgalaikį ir patikimą įrenginio veikimą, nes svoris tolygiai pasiskirsto per visą ilgį, o įdėklas nuo nusidėvėjimo saugo konstrukciją nuo pažeidimų.

- Lankstus montavimas ir integravimas. Įrenginys lengvai integruojamas į esamus įrenginius, o įvairiausios montavimo galimybės leidžia pritaikyti transporterį prie skirtingų vietos sąlygų ir reikalavimų.

- Transportavimas be užsikimšimo. Unikali spiralė, kai nereikia tarpinių ir galinių atramų, leidžia transportuoti pačias sudėtingiausias medžiagas (sausas, drėgnas, šlapias, klampias, lipnias, kibias, dulkėtas, didelių gabaritų ar abrazyvines medžiagas), užtikrinant nuolatinį ir efektyvų medžiagų transportavimą be jokių sutrikimų.

- Didelis našumas ir mažesnės energijos sąnaudos. Šis įrenginys užtikrina didelį našumą ir efektyvų energijos naudojimą, lyginant su tradiciniais veleniniais sraigtais.

- Hermetizuota sistema. Visiškai hermetizuota konstrukcija užtikrina, kad medžiagos yra saugiai transportuojamos be jokio nuostolio ar taršos.

- Plačios pritaikymo galimybės. Spiralė gali būti tiekiama net iki 30 metrų ilgio, išlaikant transportavimo efektyvumą per visą ilgį. Taip pat galima rinktis horizontalų, nuožulnų ir vertikalų montavimą arba kombinuotą montavimo variantą, dvigubą spiralinį transporterį, besisukančią arba atvirkštinę transportavimo konstrukciją. Tai suteikia išskirtines galimybes pritaikyti šį įrenginį pagal skirtingus poreikius ir sąlygas.